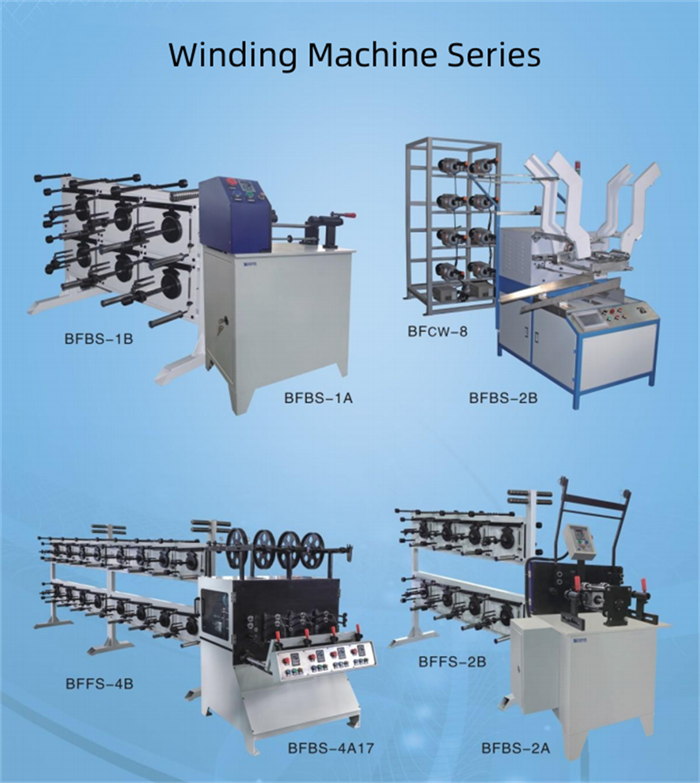

Industrial Wire Bobbin Spooling Aluminium Foil Winder

Brand: Benfa

Country of origin: China

Technical Support: Longlife

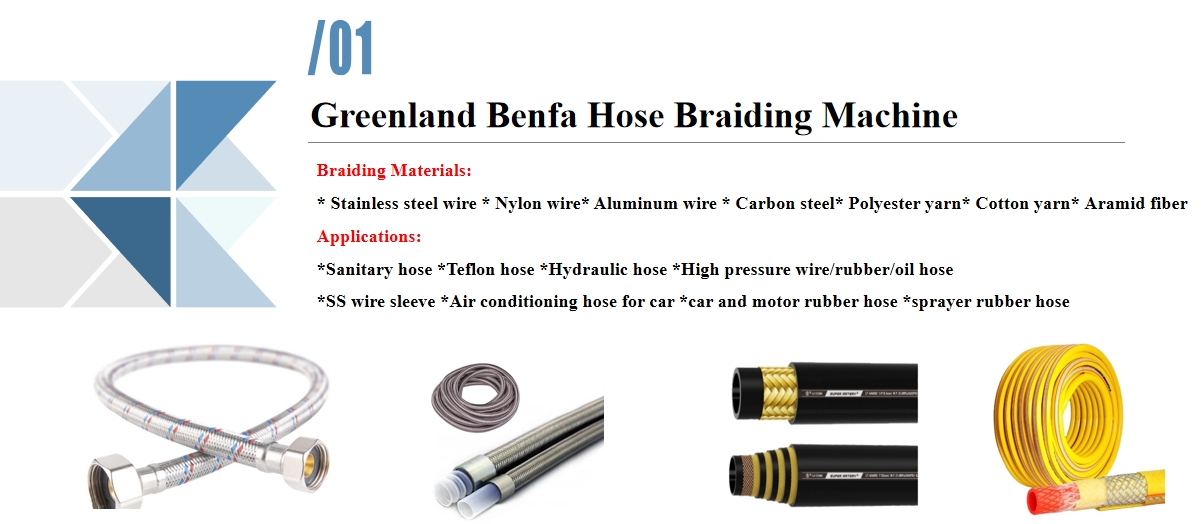

Application: *Sanitary hose *Teflon hose *Hydraulic hose *High pressure wire/rubber/oil hose *SS wire sleeve *Air conditioning hose for car *car and motor rubber hose *sprayer rubber hose

Greenland Benfa technology Industrial Wire Bobbin Spooling Aluminium Foil Winder

1) Industrial wire spooling machine offers efficient operation with one worker overseeing multiple machines.

2) Automatic bobbin winder machine Intelligent control enables the machine to stop at specified laps, and it accurately tallies the number of processed bobbins.

3) Automatic halting in case of wire breaks or depletion enhances safety.

4) Aluminium foil winding machine,the payoff unit, featuring a brake, ensures consistent tension. Moreover, custom designs for winding heads and

5) Automatic wire winding spool machine,impressive productivity is achieved with a winding speed of 105m/s.

6) payoff shafts cater to individual customer requirements, reflecting adaptability.

7) Overall, industrial Wire Bobbin Spooling Aluminium Foil Winder excels in productivity, safety, and flexibility, making it a reliable choice for diverse winding needs.

Download

Greenland Benfa technology Industrial Wire Bobbin Spooling Aluminium Foil Winde

industrial wire spooling machine,automatic bobbin winder machine,aluminium foil winding machine,automatic wire winding spool machine

Main feature:

Greenland Benfa technology Fully Automatic Yarn Hose Wire Winding Machine

One worker can watch over several machines, automatically stops when wire breaks or runs out.

Intelligent control, machine stops when set laps reached, also counts the NO. of bobbin processed

High productivity. winding speed reaches 105m/s

Pay off unit equipped with a brake keeps the tension even

Custom design for the winding head and pay off shaft per customer's request.

Specifications:

Greenland Benfa technology Fully Automatic Yarn Hose Wire Winding Machine

hose winding machine,winding machine,wire winding machine,yarn winding machine,automatic wire winding machine

Type | Axis RPM | Motor power | Voltage | Moving pitch | Bobbin size | Bobbin Qty | Pay off Spool No | Pay off Spool size |

| BFBS-1A | 1400rpm (Frequency conversion) | 0.55KWi(2 Phase)220v | 220V/50Hz | 0.05-5mm ( Traversing drive) | D≤100mm H≤280 mm (Customized ) | 1 | ≤9 | D≤200mm H≤280 mm (Customized ) |

| BFBS-1A30 | 0.75KW(2 Phase)220V | 22oV/50Hz | 1 | ≤9 | ||||

| BFBS-2A | 0.75KW(2 Phase)220V | 220V/50Hz | 2 | ≤18 | ||||

| BFBS-2B | 0.75KW | 380V/220V/5OHz | 2 | Customized | ||||

| BFBS-4A | 1.5KW(3 Phase)38Ov | 380V/220V/50Hz | 4 | ≤36 | ||||

| BFBS-4A17 | 0.55KW*4/(2 Phase)220V | 220V/50Hz | 4 | ≤36 | ||||

| BFBS-4C | 2.2KW | 220V/50Hz | 4 | ≤36 |

Type | Pay off Spool No | Pay off Spool sizo | Pay off materlal steel wire, cotton, nylon |

| BFFS-1A | 9 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-2A | 18 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1B | 12 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1B290 | 12 | 250*290cm | Steel wire, cotton thread, nylon thread |

| BFFS-1BTX | 2 | 250*200cm | carbon fibre |

| BFFS-2B | 16 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1N | 10 | 25o*200cm | cotton thread, nylon thread |

| BFFS-2N | 20 | 250*200cm | cotton thread, nylon thread |

| BFFS12-255C | 12 | 280*115cm | Steel wire |

| BFFS14-255C | 14 | 280*115cm | Steel wire |

| BFFS-PE | 16 | 250*200cm | cotton thread, nylon thread |

| BFCW-8 | 8 | 250*200cm | Steel wire, cotton thread, nylon thread |

Applications:

Greenland Benfa technology hose braiding machine widely use in different industries,such as sanitary hose , high pressure wire/rubber/oil hose, Teflon hose,

SS wire sleeve, air conditioning hose , car and motor rubber hose, sprayer rubber hose and so on.

Description:

Greenland Benfa technology Fully Automatic Yarn Hose Wire Winding Machine

hose winding machine,winding machine,wire winding machine,yarn winding machine,automatic wire winding machine

Among our diverse range of offerings are the carbon fiber filament winding machine, fully automatic winding machine, automatic spool winder, and rope winder machine.

These machines serve as indispensable accessory devices to our automatic braiding machines, enhancing the efficiency and precision of the overall braiding process.

2. As a leading hose braiding machine manufacturer, Greenland Benfa technology takes pride in offering comprehensive one-stop solutions

encompassing winding, braiding, cutting, assembly, and crimping machines. Our commitment to excellence is demonstrated

by our support for numerous braiding companies in establishing production lines, earning acclaim from prominent brands for delivering efficient and reliable solutions.

3. The carbon fiber filament winding machine, fully automatic winding machine, and automatic spool winder play a crucial role in winding wire and yarn onto bobbins evenly

and orderly. Consisting of two essential parts—the pay-off shaft and winding head—these machines can be utilized either independently or in combination.

4. Our winding machines come in various configurations, including 1 head winding machine, 2 head winding machine, and 4 head winding machine.

The versatility of these machines is a key feature, allowing one worker to oversee several machines simultaneously.

This not only maximizes operational efficiency but also ensures seamless production.

5. With a remarkable winding speed of up to 105m/s, our machines exhibit high productivity, meeting the demands of modern manufacturing.

The pay-off unit is equipped with a brake mechanism, ensuring consistent tension throughout the winding process, contributing to the quality and uniformity of the final product.

Intelligent control is a cornerstone of our winding machines, featuring automatic stop functions when wire breaks or runs out.

6. This ensures the safety of the process and minimizes material waste. Additionally, our machines boast the capability to halt operations when the set laps are reached,

counting the number of bobbins processed for accurate monitoring and control.

7. Furthermore, we offer custom design options for both the winding head and pay-off shaft, tailoring our machines to the specific requirements of our customers.

This commitment to customization ensures that our machines seamlessly integrate into diverse production environments.

In conclusion, Greenland Benfa technology's hose winding machines are a testament to our dedication to excellence in manufacturing. With intelligent control features,

high productivity, and custom design options, our winding machines stand out as reliable and efficient solutions for braiding processes.

As a key player in the industry, we continue to set the standard for hose braiding machine technology, meeting the evolving needs of our customers.