Horizontal Wire Bobbin Spool Winding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

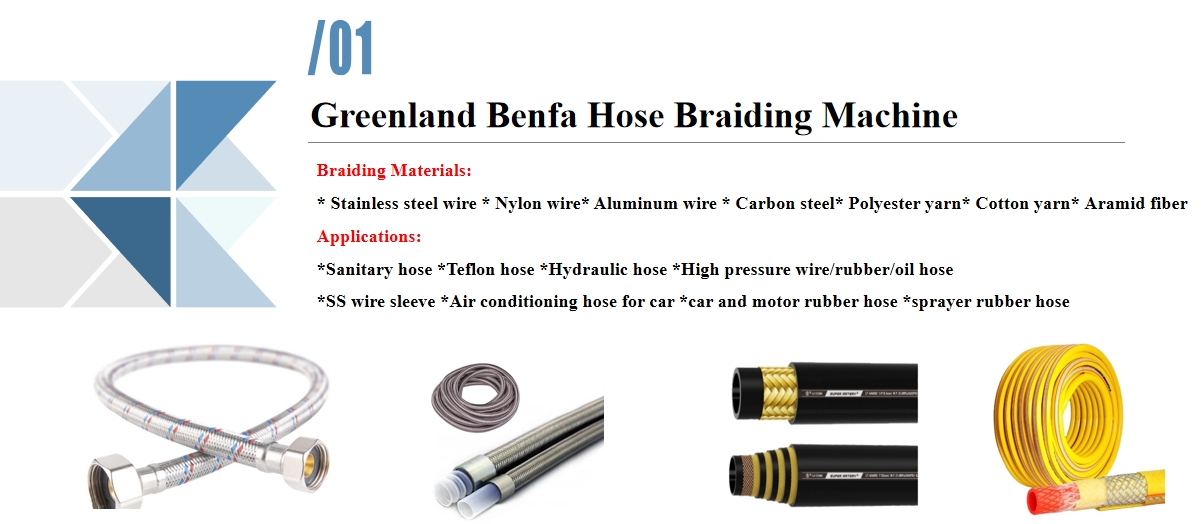

Application: *Sanitary hose *Teflon hose *Hydraulic hose *High pressure wire/rubber/oil hose *SS wire sleeve *Air conditioning hose for car *car and motor rubber hose *sprayer rubber hose

Greenland Benfa technology horizontal Wire Bobbin Spool Winding Machine

1) Horizontal winding machine wire drape difference is less than 50mm(8 wires),

2) Wire bobbin winding machine winding speed is 0-560m /min, fast, accurate and stable.

3) Metering length is accurate, and the length error of each bobbin is less than 10m.

4) Added special compensation device, with functions of sorting and winding assistance,

5) Automatic wire winding machine is convenient to change the type of formula.

6) Wire spool winding machine,metering count complete. machine error automatic stop ,When broken wire out of-wire, air pressure defect, etc.

7) Pay off system can be custom designed per request to wind up to 16 strands wires per bobbin.

Greenland Benfa technology Greenland Benfa technology horizontal Wire Bobbin Spool Winding Machine

horizontal winding machine,wire bobbin winding machine,wire spool winding machine

Main feature:

Greenland Benfa technology Greenland Benfa technology horizontal Wire Bobbin Spool Winding Machine

horizontal winding machine,wire bobbin winding machine,wire spool winding machine

Wire drape difference is less than 50mm,(8 wires), each wire is equipped with an independent control unit,

which is controlled by a precision sensor, so that the tension of the wire is kept constant.

Winding speed is 0-560m /min, fast, accurate and stable.

Metering length is accurate, and the length error of each bobbin is less than 10m.

Added special compensation device, with functions of sorting and winding assistance,

to prevent accidental wire breaking off and stop during the process of winding.

Automatic wire winding machine is convenient to change the type of formula. Enter the winding speed, bobbin size,

wire diameter, number of strands, and winding length in the user interface to automatically wind.

Metering count complete. machine error automatic stop ,When broken wire out of-wire, air pressure defect, etc.

and set length reached ,machine automatically stops and send an alarm.

Pay off system can be custom designed per request to wind up to 16 strands wires per bobbin.

Specifications:

Greenland Benfa technology Greenland Benfa technology horizontal Wire Bobbin Spool Winding Machine

horizontal winding machine,wire bobbin winding machine,wire spool winding machine

Type | Axis RPM | Motor power | Voltage | Moving pitch | Bobbin size | Bobbin Qty | Pay off Spool No | Pay off Spool size |

| BFBS-1A | 1400rpm (Frequency conversion) | 0.55KWi(2 Phase)220v | 220V/50Hz | 0.05-5mm ( Traversing drive) | D≤100mm H≤280 mm (Customized ) | 1 | ≤9 | D≤200mm H≤280 mm (Customized ) |

| BFBS-1A30 | 0.75KW(2 Phase)220V | 22oV/50Hz | 1 | ≤9 | ||||

| BFBS-2A | 0.75KW(2 Phase)220V | 220V/50Hz | 2 | ≤18 | ||||

| BFBS-2B | 0.75KW | 380V/220V/5OHz | 2 | Customized | ||||

| BFBS-4A | 1.5KW(3 Phase)38Ov | 380V/220V/50Hz | 4 | ≤36 | ||||

| BFBS-4A17 | 0.55KW*4/(2 Phase)220V | 220V/50Hz | 4 | ≤36 | ||||

| BFBS-4C | 2.2KW | 220V/50Hz | 4 | ≤36 |

Type | Pay off Spool No | Pay off Spool sizo | Pay off materlal steel wire, cotton, nylon |

| BFFS-1A | 9 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-2A | 18 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1B | 12 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1B290 | 12 | 250*290cm | Steel wire, cotton thread, nylon thread |

| BFFS-1BTX | 2 | 250*200cm | carbon fibre |

| BFFS-2B | 16 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1N | 10 | 25o*200cm | cotton thread, nylon thread |

| BFFS-2N | 20 | 250*200cm | cotton thread, nylon thread |

| BFFS12-255C | 12 | 280*115cm | Steel wire |

| BFFS14-255C | 14 | 280*115cm | Steel wire |

| BFFS-PE | 16 | 250*200cm | cotton thread, nylon thread |

| BFCW-8 | 8 | 250*200cm | Steel wire, cotton thread, nylon thread |

Applications:

Greenland Benfa technology hose braiding machine widely use in different industries,such as sanitary hose , high pressure wire/rubber/oil hose, Teflon hose,

SS wire sleeve, air conditioning hose , car and motor rubber hose, sprayer rubber hose and so on.

Description:

Greenland Benfa technology Greenland Benfa technology horizontal Wire Bobbin Spool Winding Machine

horizontal winding machine,wire bobbin winding machine,wire spool winding machine

As a leading hose braiding machine manufacturer, Greenland Benfa technology introduces the BFHG-255C series, an innovative Automatic Steel Wire

Winding Machine designed for horizontal wire bobbin spool winding. This state-of-the-art machine is a crucial component of our one-stop

braiding solutions, ensuring efficiency and precision from winding to assembly.

**Versatility and Precision:**

The BFHG-255C series excels in winding up to 16 strands of wire onto the bobbin, catering to the specific needs of wire braiding machines.

Its versatility makes it indispensable in steel wire production, manufacturing steel wire braided hydraulic hoses, stainless steel wire sleeves, and more.

**Three-Part Design:**

This automatic steel wire winding machine comprises three essential parts—winding head, pay-off system, and electric control system.

The integration of these components ensures a seamless and efficient wire winding process.

**Wire Tension Control:**

A standout feature is the precise control of wire tension. Each wire is equipped with an independent control unit, precisely regulated by a sensor.

This design ensures that the wire drape difference is less than 50mm (for 8 wires), maintaining constant tension throughout the winding process.

**High-Speed Winding:**

The winding speed of this machine is impressive, ranging from 0 to 560m/min. This high-speed capability is coupled with accuracy and stability,

ensuring fast and reliable wire winding.

**Accurate Metering:**

The BFHG-255C series guarantees accurate metering length, with the length error of each bobbin being less than 10m.

This precision is vital for maintaining quality standards in the final product.

**Special Compensation Device:**

To enhance reliability, a special compensation device is incorporated. This feature includes sorting and winding assistance functions,

preventing accidental wire breakage and stopping during the winding process.

**User-Friendly Interface:**

Changing the winding formula is made convenient through the user interface. Operators can input parameters such as winding speed, bobbin size,

wire diameter, number of strands, and winding length, allowing for automatic winding according to the specified requirements.

**Safety Features:**

The machine is equipped with safety features such as automatic stop in case of broken wire, air pressure defects, or when the set length is reached.