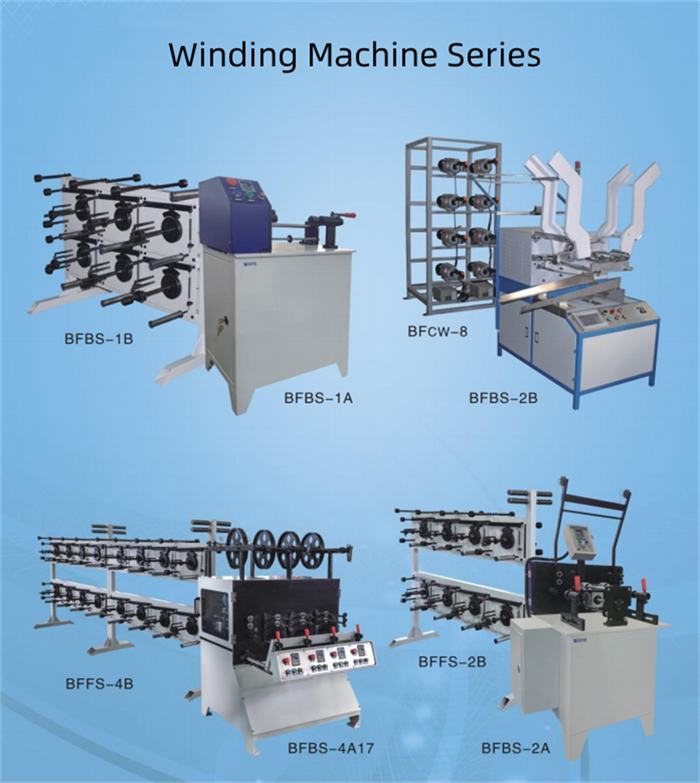

Bobbin Wire Spool Cable Yarn Winding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

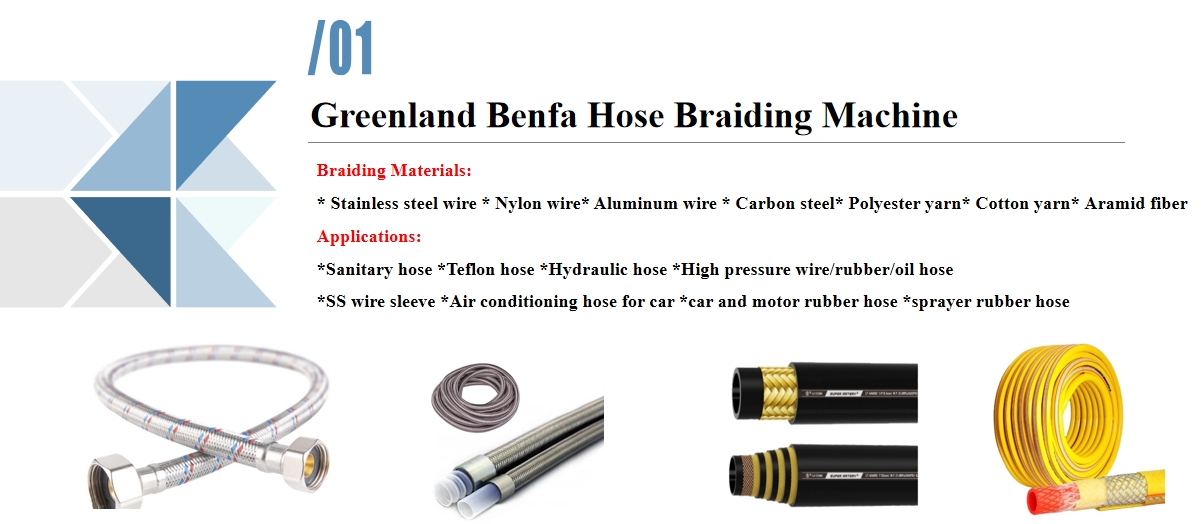

Application: *Sanitary hose *Teflon hose *Hydraulic hose *High pressure wire/rubber/oil hose *SS wire sleeve *Air conditioning hose for car *car and motor rubber hose *sprayer rubber hose

Bobbin Wire Spool Cable Yarn Winding Machine

1.Winding machine offers efficient operation with one worker overseeing multiple machines.

2. Automatic halting in case of wire breaks or depletion enhances safety.

3.Intelligent control enables the machine to stop at specified laps, and it accurately tallies the number of processed bobbins.

4.High productivity, winding speed up to 105m/s.

5.payoff shafts cater to individual customer requirements, reflecting adaptability.

Overall, bobbin wire spool cable yarn winding machine in productivity, safety, and flexibility, making it a reliable choice for diverse winding needs.

Greenland Benfa technology Bobbin Wire Spool Cable Yarn Winding Machine

bobbin winding machine,spool winding machine,wire spool winder,automatic cable winding machine,automatic yarn winding machine

Main feature:

Greenland Benfa technology Fully Automatic Yarn Hose Wire Winding Machine

One worker can watch over several machines, automatically stops when wire breaks or runs out.

Intelligent control, machine stops when set laps reached, also counts the NO. of bobbin processed

High productivity. winding speed reaches 105m/s

Pay off unit equipped with a brake keeps the tension even

Custom design for the winding head and pay off shaft per customer's request.

Specifications:

Greenland Benfa technology Fully Automatic Yarn Hose Wire Winding Machine

hose winding machine,winding machine,wire winding machine,yarn winding machine,automatic wire winding machine

Type | Axis RPM | Motor power | Voltage | Moving pitch | Bobbin size | Bobbin Qty | Pay off Spool No | Pay off Spool size |

| BFBS-1A | 1400rpm (Frequency conversion) | 0.55KWi(2 Phase)220v | 220V/50Hz | 0.05-5mm ( Traversing drive) | D≤100mm H≤280 mm (Customized ) | 1 | ≤9 | D≤200mm H≤280 mm (Customized ) |

| BFBS-1A30 | 0.75KW(2 Phase)220V | 22oV/50Hz | 1 | ≤9 | ||||

| BFBS-2A | 0.75KW(2 Phase)220V | 220V/50Hz | 2 | ≤18 | ||||

| BFBS-2B | 0.75KW | 380V/220V/5OHz | 2 | Customized | ||||

| BFBS-4A | 1.5KW(3 Phase)38Ov | 380V/220V/50Hz | 4 | ≤36 | ||||

| BFBS-4A17 | 0.55KW*4/(2 Phase)220V | 220V/50Hz | 4 | ≤36 | ||||

| BFBS-4C | 2.2KW | 220V/50Hz | 4 | ≤36 |

Type | Pay off Spool No | Pay off Spool sizo | Pay off materlal steel wire, cotton, nylon |

| BFFS-1A | 9 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-2A | 18 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1B | 12 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1B290 | 12 | 250*290cm | Steel wire, cotton thread, nylon thread |

| BFFS-1BTX | 2 | 250*200cm | carbon fibre |

| BFFS-2B | 16 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1N | 10 | 25o*200cm | cotton thread, nylon thread |

| BFFS-2N | 20 | 250*200cm | cotton thread, nylon thread |

| BFFS12-255C | 12 | 280*115cm | Steel wire |

| BFFS14-255C | 14 | 280*115cm | Steel wire |

| BFFS-PE | 16 | 250*200cm | cotton thread, nylon thread |

| BFCW-8 | 8 | 250*200cm | Steel wire, cotton thread, nylon thread |

Applications:

Greenland Benfa technology hose braiding machine widely use in different industries,such as sanitary hose , high pressure wire/rubber/oil hose, Teflon hose,

SS wire sleeve, air conditioning hose , car and motor rubber hose, sprayer rubber hose and so on.

Description:

The Bobbin Cable Yarn Winder represents a leap forward in yarn winding technology. Unlike traditional winding machines, which often require manual intervention and are prone to inconsistencies, this cutting-edge equipment automates the entire winding process with precision and reliability.

main feature:

1.Automation: The bobbin spool cable yarn winding machine automates the entire yarn winding process, from feeding the yarn to winding it onto the bobbin or bobbin. This automation significantly reduces labor costs and eliminates human error, ensuring consistent, high-quality output.

2. High production efficiency: With its advanced electric mechanism and optimized winding algorithm, the bobbin spool cable yarn winding machine operates at its high speed, greatly improving production efficiency.

3. Quality Control: Built-in sensors and monitoring systems ensure that each spool maintains consistent tension and thickness throughout the entire winding process. This level of quality control minimizes defects and increases the overall reliability of the yarn, meeting the stringent standards of the textile industry.

4. Versatility: This automatic winding machine is designed to accommodate a variety of yarn types and thicknesses, making it suitable for a variety of textile applications. Whether it is filament yarn or strong cable yarn, the bobbin cable yarn winding machine can handle it with ease.

The Greenland Benfa Bobbin Cable Yarn Winder revolutionizes the yarn winding process with its combination of automation, versatility, speed and quality control. Greenland Benfa is known for providing complete hose braiding solutions covering hose winding machines, hose braiding machines, hose cutting machines, hose assembly machines and hose crimping machines. Also offers unbeatable ex-factory prices and comprehensive hose braiding machine OEM/ODM services, including installation, maintenance and spare parts supply.