Copper Belt Stainless Steel Hose Braiding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: sanitary, cable,car and motor hose,high-pressure hose industries,

Carrier Per Deck: 16,20,32,36,48

Braided Hose OD: 16,20,32,36,48mm

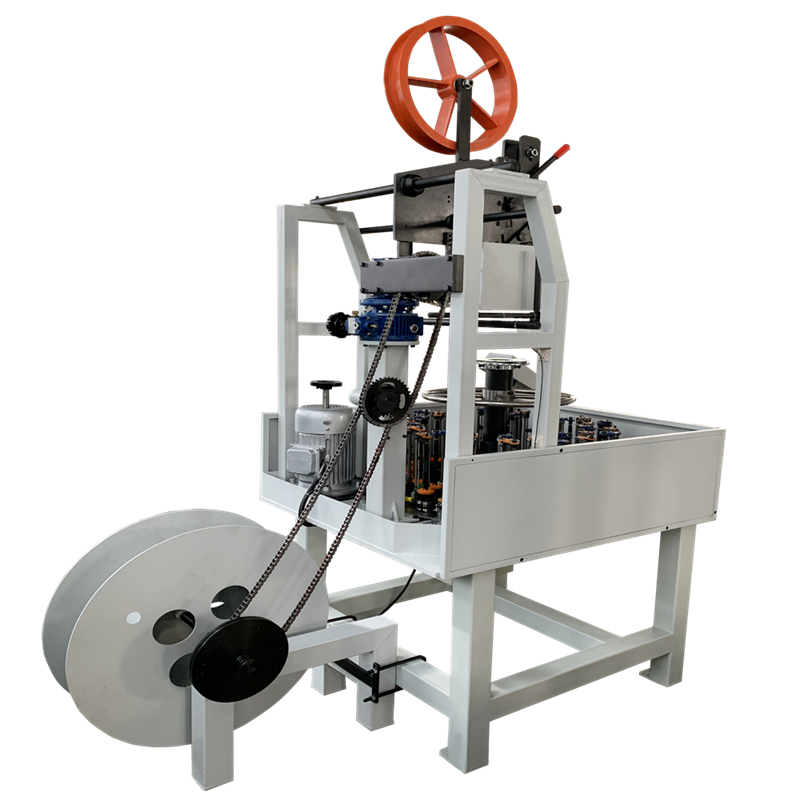

Greenland Benfa's Copper Belt Stainless Steel Hose Braiding Machine stands out with its cutting-edge technology. This hose braiding machine, designed for stainless steel and copper belt applications, boasts high automation for seamless operation. Its adjustable speed eliminates the need for gear changes, enhancing adaptability and user convenience. The machine excels in efficiency, achieving high-speed production with low noise levels, ensuring a quieter working environment. Easy maintenance and customization options further contribute to its appeal, making it a versatile and reliable choice for the production of braided hoses with copper and stainless steel materials.

Download

Greenland Benfa techology Copper Belt Stainless Steel Hose Braiding Machine

hose stainless Steel braiding machine,Copper Belt Braiding Machine,copper braiding machine,copper wire braiding machine

Copper Belt Braiding Machine

copper wire braiding machine

Main feature:

High automatic extent broken ,empty bobbin or no tube automatic machine self-closed.

Adopt adjustable speed to accommodate pitch. don't need to change gear.

High efficiency production three times than present usual machine per hour ,the max production reach to 98m/hour

Low noise ,transmission and pulling system adopt absorbing sound ,reducing shake and inserting equipment.

Easy maintenance ,transmission flexible structure easy install and remove

We can design the machine as customer request.

Specifications:

Greenland Benfa technology hose braiding machine 140 series Automatic Hose Braiding Machine has different specifications.

Copper Belt Stainless Steel Hose Braiding Machine

hose stainless Steel braiding machine,Copper Belt Braiding Machine,copper braiding machine,copper wire braiding machine

| Type | carrier per deck | carrier speed [RPM] | braiding machine power | haul off motor power | braiding pitch set up | carrier tension | braided hose OD | Weight |

| BFB16L-140CFS | 16 | 55rpm(max) | 1.5KW*2 | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤16mm | 300kg |

| BFB20L_140B | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L_140B II | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L-140BF | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L-140CF | 20 | 44rpm(max) | 1.5KW | 0.55Kw | electronic parameter set | 0.4kg-5.0kg | ≤20mm | 350kg |

| BFB24L-140CFS | 24 | 42rpm(max) | 1.5KW*2 | 0.55KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 580kg |

| BFB24L-140AF | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140AF II | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140B | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140B II | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140BF | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140CF | 24 | 42rpm(max) | 1.5KW | 0.55KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 380kg |

| BFB20L+24L-140CFS I | 24 | 37rpm(max) | 1.5KW*2 | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 700kg |

| BFB24L+24L-140CFS I | 24 | 37rpm(max) | 1.5KW*2 | 0.75Kw | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 700kg |

| BFB24L-140CS | 24 | 37rpm(max) | 1.5KW*2 | 0.55Kw | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 630kg |

| BFB24L-140D | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140DI | 24 | 37rpm(max) | 1.5xW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB32L-140A | 32 | 28rpm(max) | 2 2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤32mm | 430kg | |

| BFB32-140B | 32 | 28rpm(max) | 2 2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤32mm | 430kg | |

| BFB32L-140CF | 32 | 28rpm(max) | 2.2KW | 0.75KW | ectronic pararmeter set | 0.4kg-5.0kg | ≤32mm | 430kg |

| BFB36L-140AF | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140B | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140BF | 36 | 29rpm(max) | 2 2xw | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140CF | 36 | 29rpm(max) | 2.2KW | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤36mm | 520kg |

| BFB36L-140D | 36 | 29rpm(max) | 3.0KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB48L-140B | 48 | 25rpm(max) | 3.0KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤48mm | 550kg | |

| BFB48L-140CF | 48 | 25rpm(max) | 3.0Kw | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤48mm | 550kg |

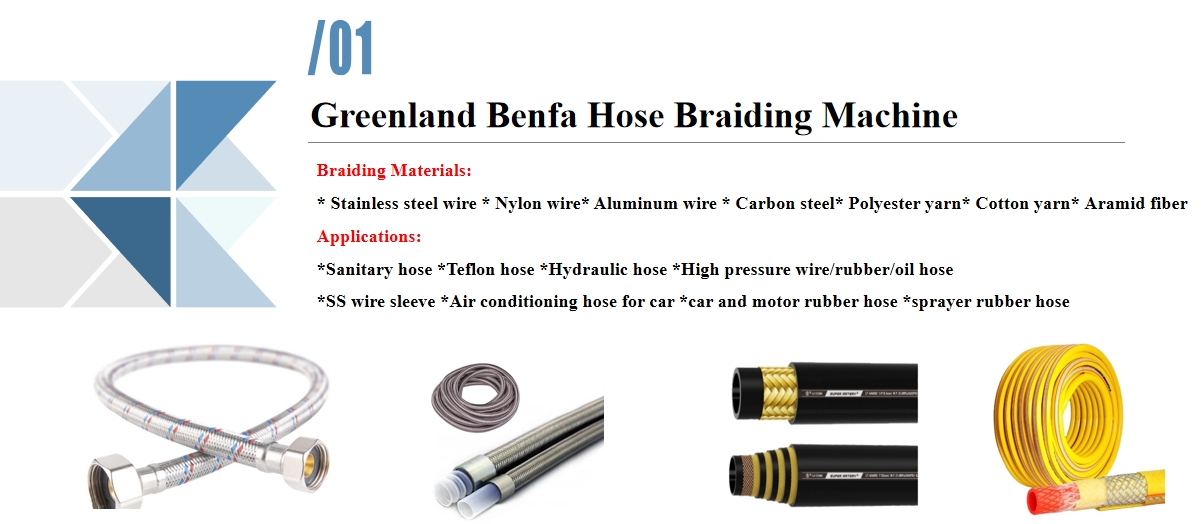

Applications:

Greenland Benfa hose braiding machine widely use in different industries,such as sanitary hose , high pressure wire/rubber/oil hose, Teflon hose,

SS wire sleeve, air conditioning hose , car and motor rubber hose, sprayer rubber hose and so on.

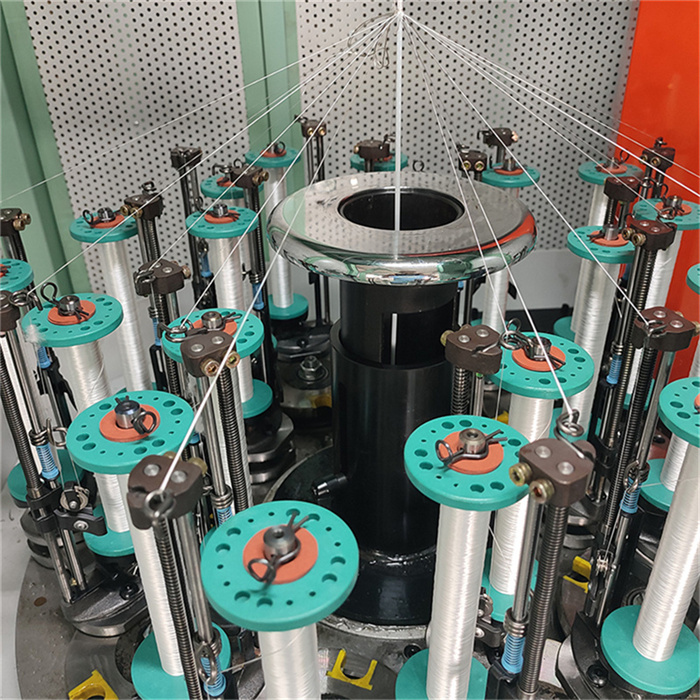

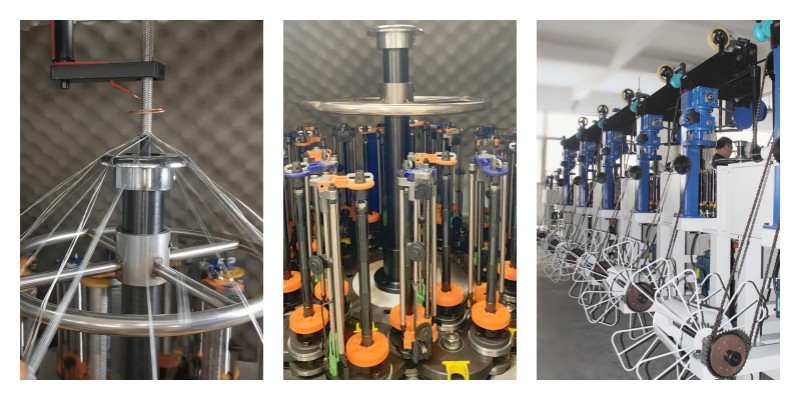

Product Detail:

Greenland Benfa technology hose braiding machine details as below photos:

Description:

Greenland Benfa technology hose braiding machine140L:with horn gear OD140mm,suitable for bobbin OD ≤ 82mm

Copper Belt Stainless Steel Hose Braiding Machine

hose stainless Steel braiding machine,Copper Belt Braiding Machine,copper braiding machine,copper wire braiding machine

carriers per deck | bobbin dimension |

8-96 | 80×28×277mm |

carrier speed [RPM] | bobbin capacity |

20-55 | 130 cm3-360 cm3 |

Greenland Benfa takes a leap forward in hose braiding technology with the Copper Belt Stainless Steel Hose Braiding Machine, a part of their innovative arsenal.

This machine is designed for the meticulous braiding of hoses using stainless steel and copper belt materials. Additionally, Greenland Benfa introduces

the 140L Series Vertical Braiding Machine, tailored for applications in the sanitary cable, car, and motor hose, as well as high-pressure rubber hose fields,

utilizing materials such as stainless steel wire and textile glass fiber.

**Copper Belt Stainless Steel Hose Braiding Machine:**

This advanced machine is a pinnacle of technology, combining the durability of stainless steel with the conductivity of copper,

catering to a diverse range of applications. Here are the key features that make it shine:

1. **High Automation:** The machine boasts a high level of automation, streamlining the braiding process with an automatic extent for handling broken wires,

empty bobbins, or situations with no tubing. This self-closed mechanism enhances operational efficiency.

2. **Adjustable Speed:** Greenland Benfa prioritizes adaptability by adopting adjustable speed, eliminating the need to change gears.

This innovative feature simplifies the operational process and enhances overall flexibility.

3. **Efficient Production:** The Copper Belt Stainless Steel Hose Braiding Machine achieves remarkable efficiency, producing three times more than present usual machines per hour.

The maximum production speed reaches an impressive 98 meters per hour, ensuring a significant boost in manufacturing output.

4. **Low Noise Operation:** Noise reduction is a key focus, with the transmission and pulling systems adopting sound-absorbing features.

This minimizes noise levels, reduces shake during operation, and enhances the overall workplace environment.

5. **Easy Maintenance:** The machine's transmission system is designed with a flexible structure, facilitating easy installation and removal.

This emphasis on easy maintenance ensures minimal downtime, contributing to increased productivity.

6. **Customization Options:** Greenland Benfa recognizes the importance of meeting specific customer requirements.

The Copper Belt Stainless Steel Hose Braiding Machine can be customized, providing tailored solutions for unique manufacturing needs.

**140L Series Vertical Braiding Machine:**

This series, designed for a variety of applications, emphasizes adaptability and efficiency. The key features of the 140L Series are:

1. **High Automation:** Similar to the Copper Belt Stainless Steel Hose Braiding Machine, the 140L Series exhibits a high level of automation.

It efficiently handles broken wires, empty bobbins, and situations with no tubing, contributing to a streamlined braiding process.

2. **Adjustable Speed:** Adaptability is a core feature, with adjustable speed accommodating different pitches without the need for gear changes.

This enhances operational efficiency and simplifies the braiding process.

3. **Efficient Production:** Boasting a production speed three times higher than conventional machines, the 140L Series achieves a maximum production rate of 98 meters per hour.

This efficiency significantly contributes to increased output in manufacturing processes.

4. **Low Noise Operation:** Noise reduction is achieved through sound-absorbing features in the transmission and pulling systems.

This ensures a quieter working environment and smoother production processes.

5. **Easy Maintenance:** The machine's transmission system features a flexible structure, simplifying installation and removal. T

his emphasis on easy maintenance enhances the overall user experience, reducing downtime and increasing productivity.

6. **Customization Options:** Acknowledging the diverse needs of manufacturers, Greenland Benfa provides customization options for the 140L Series,

ensuring the machine can be tailored to specific requirements.

**Technical Specifications for Both Machines:**

Carriers per deck range from 8 to 96, with bobbin dimensions of 80×28×277mm. The carrier speed ranges from 20 to 55 RPM, and the bobbin capacity spans from 130 cm³ to 360 cm³.

These technical specifications highlight the adaptability and versatility of both the Copper Belt Stainless Steel Hose Braiding Machine and the 140L Series Vertical Braiding Machine.

In conclusion, Greenland Benfa's commitment to technological innovation is evident in both the Copper Belt Stainless Steel Hose Braiding Machine and the 140L Series Vertical Braiding Machine.

These machines represent a new era in hose braiding technology, offering efficiency, adaptability, and customization options to meet the diverse and evolving needs of the manufacturing industry. The repeated emphasis on Greenland Benfa technology, along with the specific applications like car and motor rubber hose braiding machines, underscores the brand's prominence and reliability in the competitive landscape of hose braiding machinery.