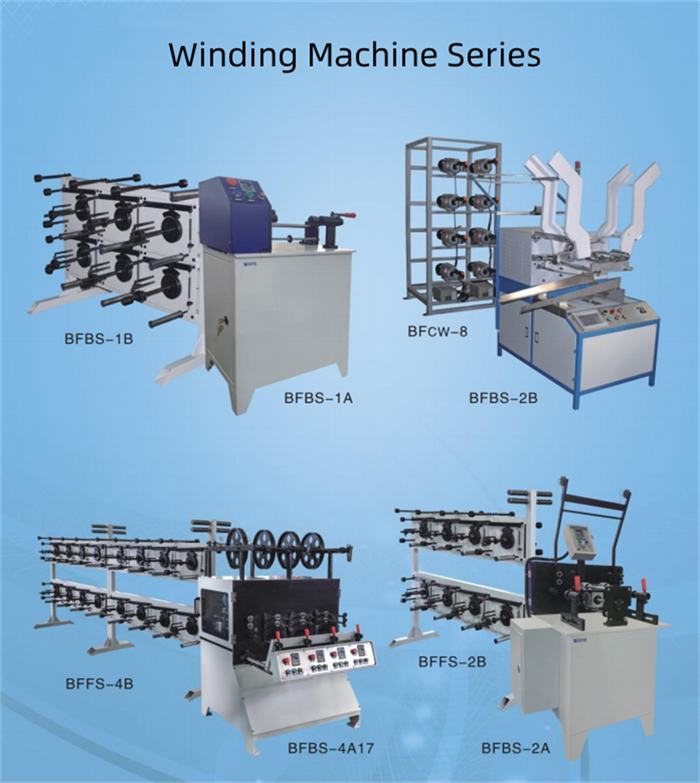

Fully Automatic Yarn Hose Wire Winding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

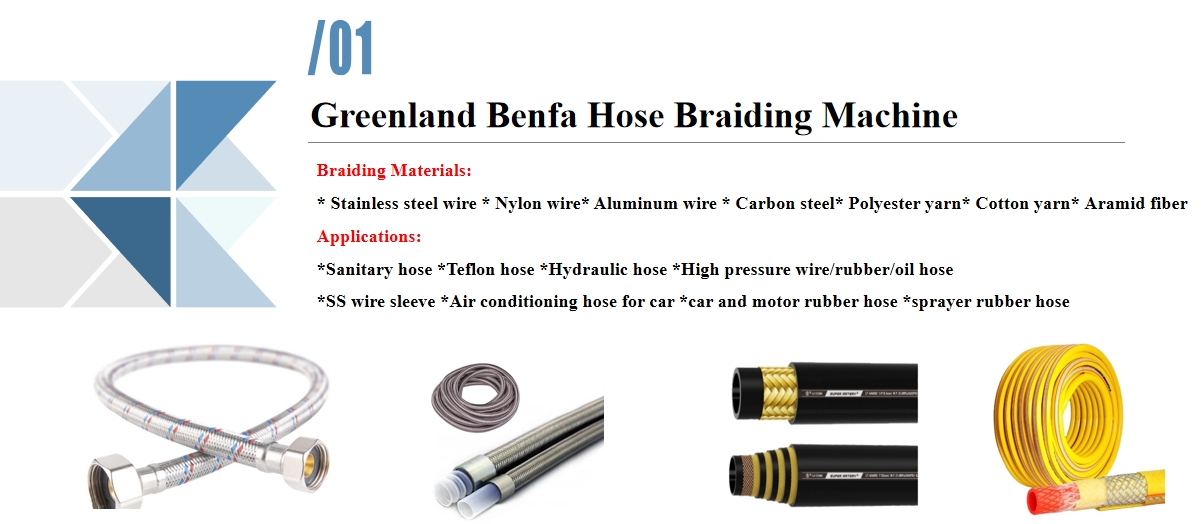

Application: *Sanitary hose *Teflon hose *Hydraulic hose *High pressure wire/rubber/oil hose *SS wire sleeve *Air conditioning hose for car *car and motor rubber hose *sprayer rubber hose

Fully automatic yarn hose winding machine

1. The machine enables efficient operation, with one worker responsible for managing multiple machines.

2. Automatically stops when disconnected or exhausted to improve safety.

3. Intelligent control enables the machine to stop according to the specified number of turns and accurately count the number of processed bobbins.

4. High productivity, the winding speed can reach 105m/s.

5. The design of the pay-off spool can be customized according to customer requirements, reflecting adaptability.

Overall, the fully automatic yarn hose winding machine excels in terms of productivity, safety, and flexibility, making it a reliable choice for a variety of winding needs.

Download

Greenland Benfa technology Fully Automatic Yarn Hose Wire Winding Machine

hose winding machine,winding machine,wire winding machine,yarn winding machine,automatic wire winding machine

Main feature:

Greenland Benfa technology Fully Automatic Yarn Hose Wire Winding Machine

One worker can watch over several machines, automatically stops when wire breaks or runs out.

Intelligent control, machine stops when set laps reached, also counts the NO. of bobbin processed

High productivity. winding speed reaches 105m/s

Pay off unit equipped with a brake keeps the tension even

Custom design for the winding head and pay off shaft per customer's request.

Specifications:

Greenland Benfa technology Fully Automatic Yarn Hose Wire Winding Machine

hose winding machine,winding machine,wire winding machine,yarn winding machine,automatic wire winding machine

Type | Axis RPM | Motor power | Voltage | Moving pitch | Bobbin size | Bobbin Qty | Pay off Spool No | Pay off Spool size |

| BFBS-1A | 1400rpm (Frequency conversion) | 0.55KWi(2 Phase)220v | 220V/50Hz | 0.05-5mm ( Traversing drive) | D≤100mm H≤280 mm (Customized ) | 1 | ≤9 | D≤200mm H≤280 mm (Customized ) |

| BFBS-1A30 | 0.75KW(2 Phase)220V | 22oV/50Hz | 1 | ≤9 | ||||

| BFBS-2A | 0.75KW(2 Phase)220V | 220V/50Hz | 2 | ≤18 | ||||

| BFBS-2B | 0.75KW | 380V/220V/5OHz | 2 | Customized | ||||

| BFBS-4A | 1.5KW(3 Phase)38Ov | 380V/220V/50Hz | 4 | ≤36 | ||||

| BFBS-4A17 | 0.55KW*4/(2 Phase)220V | 220V/50Hz | 4 | ≤36 | ||||

| BFBS-4C | 2.2KW | 220V/50Hz | 4 | ≤36 |

Type | Pay off Spool No | Pay off Spool sizo | Pay off materlal steel wire, cotton, nylon |

| BFFS-1A | 9 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-2A | 18 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1B | 12 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1B290 | 12 | 250*290cm | Steel wire, cotton thread, nylon thread |

| BFFS-1BTX | 2 | 250*200cm | carbon fibre |

| BFFS-2B | 16 | 250*200cm | Steel wire, cotton thread, nylon thread |

| BFFS-1N | 10 | 25o*200cm | cotton thread, nylon thread |

| BFFS-2N | 20 | 250*200cm | cotton thread, nylon thread |

| BFFS12-255C | 12 | 280*115cm | Steel wire |

| BFFS14-255C | 14 | 280*115cm | Steel wire |

| BFFS-PE | 16 | 250*200cm | cotton thread, nylon thread |

| BFCW-8 | 8 | 250*200cm | Steel wire, cotton thread, nylon thread |

Applications:

Greenland Benfa technology hose braiding machine widely use in different industries,such as sanitary hose , high pressure wire/rubber/oil hose, Teflon hose,

SS wire sleeve, air conditioning hose , car and motor rubber hose, sprayer rubber hose and so on.

Description:

Greenland Benfa technology Fully Automatic Yarn Hose Wire Winding Machine

hose winding machine,winding machine,wire winding machine,yarn winding machine,automatic wire winding machine

The hose winding machine is an essential accessory device designed to complement automatic braiding machines, facilitating the efficient winding of wire and yarn onto bobbins

with precision and orderliness. Comprising two integral parts—the pay-off shaft and winding head—this versatile machine can operate independently or in a combined

configuration to meet diverse manufacturing needs.

At its core, the hose winding machine plays a pivotal role in the production of hoses by ensuring the systematic arrangement and even distribution of materials onto bobbins.

The pay-off shaft serves as the initial point, guiding the wire or yarn smoothly into the winding process. This critical component ensures a continuous and controlled supply of the material,

contributing to the overall efficiency of the winding operation.

The winding head, the second key element, is responsible for the meticulous layering of the wire or yarn onto the bobbin. The standalone configuration allows for single-head winding,

suitable for specific applications. Meanwhile, the 2-head and 4-head winding machines offer increased productivity and versatility by simultaneously handling multiple bobbins, optimizing production processes.

Whether used independently or in combination, the hose winding machine enhances the capabilities of automatic braiding systems, streamlining the manufacturing of hoses for various industries.

ts adaptability and variable head configurations make it a valuable asset for manufacturers seeking efficiency, precision, and scalability in their production processes.

In conclusion, the hose winding machine stands as a crucial link in the chain of automated braiding machinery, providing the necessary functionality to wind wire and yarn systematically onto bobbins,

thereby contributing to the seamless production of high-quality hoses across diverse industries.