stainless wire rubber hose braiding machine high pressure hose braiding machine hydraulic hose braiding making machine

Brand: huibang

Country of origin: China

Technical Support: Longlife

high pressure hose braiding machine,Our braiders operate with high precision, and at the heart of the machine is the carrier. It plays a crucial role in setting and controlling the tension of the wire or yarn while ensuring optimal guidance through the process.hydraulic hose braiding machine.hydraulic hose making equipment

steel wire braiding machine for salestainless wire rubber hose braiding machine hydraulic hose braiding machine

hydraulic hose making equipment

high pressure hose braiding machine

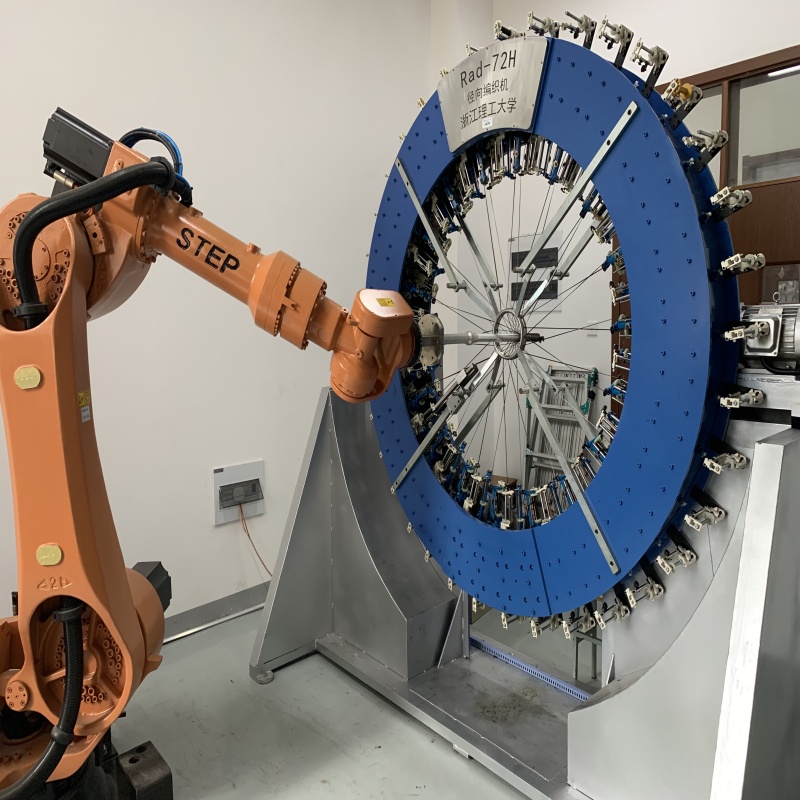

Overview of the wire braider Braiding Machine:

Our braiding machine is an innovative model our company developed based on the RB-2 braiding machine structure. This machine offers high braiding speed and enhanced production efficiency.

It employs a double-rotating thread-passing design, with the inner and outer spindle groups rotating in opposite directions. Each spindle group’s rotation direction remains unchanged during the braiding process.

The movement paths of the inner and outer spindles are circular and shorter than those of other braiding machines, allowing for a faster operational speed.

Highlights of the BZR Braiding Machine steel wire braiding machine for sale :

hydraulic hose braiding machine

hydraulic hose making equipment

1. Large spindle wire capacity: 14KG per spindle (steel wire).

2. The spindle compensation device balances the distance difference between the outer ring and the opposite braid point of the inner ring, maintaining fabric tension within 76-90% of the spindle pay-off tension. It features a stepless pay-off structure for long service life and low failure rate.

3. High running speed.

4. Independent motors drive the main engine and tractor. With PLC control and an intuitive interface, both are precisely managed to meet optimal braiding process requirements.

5. Slow tram drive functionality.

6. Independent drive for the tractor.

7. Automatic lubrication system.

8. Equipped with detection systems for broken wires, tube blanks, and medium film, along with tension monitoring. The machine automatically alarms and stops if any issue arises.

9. Intelligent fault alarm and parking prompt function.

stainless wire braiding machine

rubber hose braiding machine

high pressure hose braiding machine

hydraulic hose braiding machine

hydraulic hose making equipment

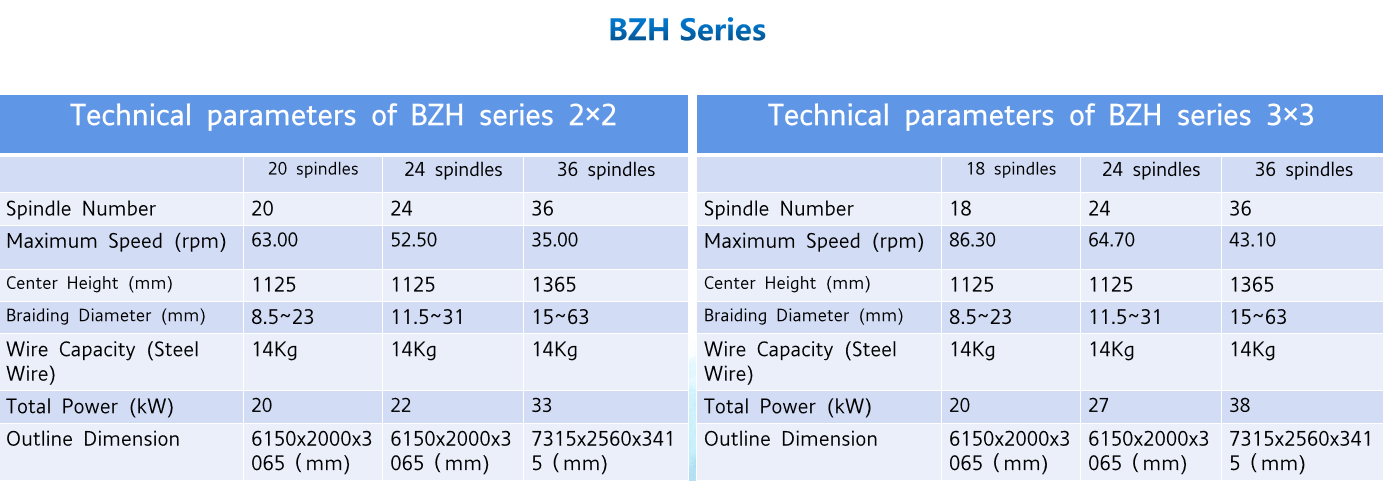

Specifications:

ruber hose making Applications:

*Hydraulic hose *High pressure wire/rubber/oil hose *SS wire sleeve *Air conditioning hose for car *car and motor rubber hose *sprayer rubber hose

our hose making machine can produce below ruber hose specifications.

| TYPE | SIZE(") | IN(mm) | OD(mm) |

| SAE J517 100 R1AT | 1/4 | 6.4 | 12.6 |

| SAE J517 100 R1AT | 5/16 | 7.9 | 14.3 |

| SAE J517 100 R1AT | 3/8 | 9.5 | 16.5 |

| SAE J517 100 R1AT | 1/2 | 12.7 | 19.6 |

| SAE J517 100 R1AT | 5/8 | 15.9 | 22.8 |

| SAE J517 100 R1AT | 3/4 | 19.0 | 26.7 |

| SAE J517 100 R1AT | 1 | 25.4 | 34.9 |

| SAE J517 100 R1AT | 1 1/4 | 31.8 | 42.6 |

| SAE J517 100 R1AT | 1 1/2 | 38.1 | 49.6 |

| SAE J517 100 R1AT | 2 | 50.8 | 62.6 |

| SAE J517 100 R2AT | 1/4 | 6.4 | 14.2 |

| SAE J517 100 R2AT | 5/16 | 7.9 | 16.0 |

| SAE J517 100 R2AT | 3/8 | 9.5 | 18.0 |

| SAE J517 100 R2AT | 1/2 | 12.7 | 21.2 |

| SAE J517 100 R2AT | 5/8 | 15.9 | 24.2 |

| SAE J517 100 R2AT | 3/4 | 19.0 | 28.2 |

| SAE J517 100 R2AT | 1 | 25.4 | 36.5 |

| SAE J517 100 R2AT | 1 1/4 | 31.8 | 46.6 |

| SAE J517 100 R2AT | 1 1/2 | 38.1 | 53.4 |

| SAE J517 100 R2AT | 2 | 50.8 | 66.2 |

| DIN20023 EN856 4SH | 3/8 | 9.5 | 21.0 |

| DIN20023 EN856 4SH | 1/2 | 12.7 | 24.2 |

| DIN20023 EN856 4SH | 5/8 | 15.9 | 27.7 |

| DIN20023 EN856 4SH | 3/4 | 19.0 | 31.8 |

| DIN20023 EN856 4SH | 1 | 25.4 | 38.5 |

| DIN20023 EN856 4SH | 1 1/4 | 31.8 | 46.0 |

| DIN20023 EN856 4SH | 1 1/2 | 38.1 | 53.3 |

| DIN20023 EN856 4SH | 2 | 50.8 | 67.1 |