hydraulic hose Composite Hose steel wire making machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: steel wire braided high pressure rubber tube ,steel wire braided sleeve , braided corrugated tube , high strength wire braided tube. Big diameter cable brake hose ,air conditioner hose

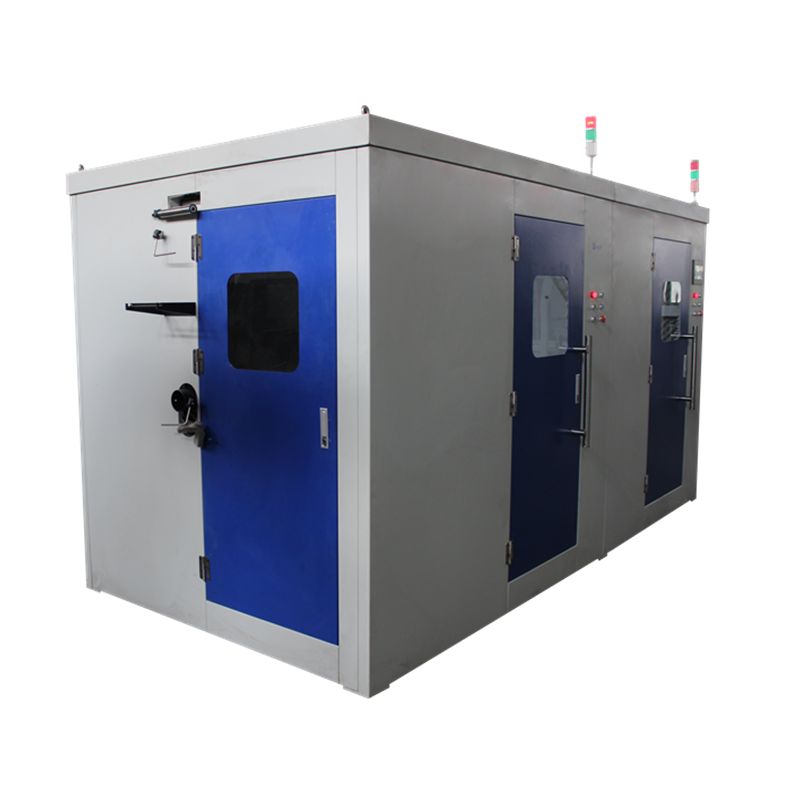

Greenland Benfa techology Horizontal Hydraulic Wire Hose Braiding Machine

Product Description:

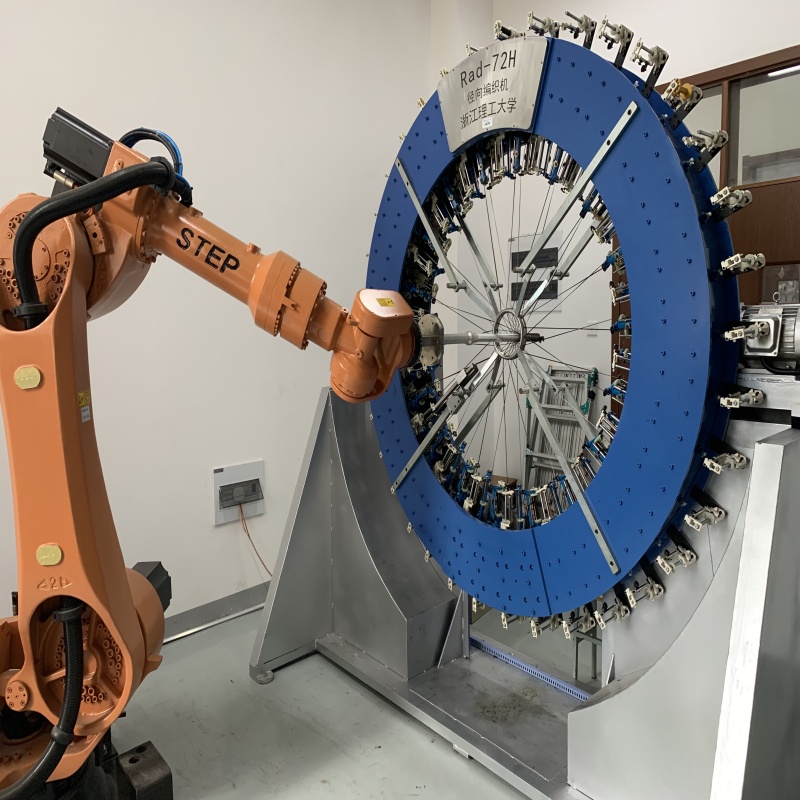

The GLT Rotary Braider represents a breakthrough in steel wire braiding technology. Operating on the principle of controlled rotation, its spindle moves along a circular straight line, departing from the traditional 8-word handover principle used globally. This innovative design ensures stability and precision in braiding.The GLT Rotary Braider features inner and outer turn tables that rotate in opposite directions at high speeds, significantly increasing production output compared to traditional Maypole type braiders.Available in various models (GLT-90, 114, 140, 200, 240, 300), the GLT horizontal hose automatic braiding machine is extensively utilized in wire and cable production, manufacturing pressure-resistant braided rubber pipes, water heating hoses, rope belts, automotive rubber hoses, spray rubber pipes, Teflon pipes, high-pressure pipes, and other industries.

Advantage:

This machine adopts the principle of controlled rotation and the circular linear motion of spindle, which guarantees the stability of the tension force and improves the quality of weaving products.

The design of shaping driving mechanism makes the braiding more accurate, improves the braiding accuracy and greatly improves the braiding quality.

The design of circular linear motion of the spindle improves the spindle speed and greatly improves the production efficiency.

The large capacity of the line saves the waste of steel wire, reduces the frequency of wire transfer, improves the working efficiency, and reduces the production cost.

The fully enclosed muffling structure ensures the safe production of the operators and optimizes the working environment.

Automatic digital control is adopted to improve the mechanical precision, reduce the worker's operating skills, and achieve a one-person operation of multiple machines.

Door control stop alarm function.

Offline automatic parking function.

Man-Machine interface parameter setting.

Fixed Length Braiding Function.

Fault prompt function.

Three color alarm prompt.

Application:

* Shielding for wire and cable products

* Sanitary hose (Plumbing hose) product

* Teflon hose

* Low pressure hose and high pressure hose

* Irony steam hose

* Refrigerating fluid charge hose

* Hydraulic hose

Braiding Material :

* Polyester yarn

* Carbon steel

* Stainless steel wire (0.10-0.35mm)

* Nylon wire

* Alumium wire (0.15-0.30mm)

* Cotton yarn

* Aramid fiber