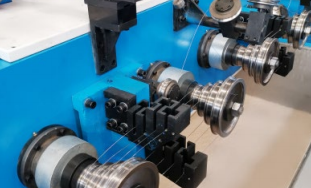

welding wire turn over wet wire drawing process machine

welding wire turn over wet wire drawing process machine

multi wet wire drawing machine wire drawing equipment wire drawing machine

In the wire drawing production process,greenland youmale wire drawing machine has shifted from the traditional method of using one model for drawing wires of various materials. Now, different materials are drawn using models specifically designed for each type of wire. Furthermore, based on the wire rod's specifications, multiple models within the same series are dedicated to specialized machines. The drawing process is customized according to the wire rod's material.

Here’s a repetition of the features you provided:

- **Suitable drawing materials**: steel wire (high carbon, medium carbon, low carbon wire, stainless steel wire, prestressed steel wire, bead steel wire, hose steel wire, spring steel wire, cord steel wire, etc.).

- **Cooling system**: The reel adopts slit water cooling, and the wire drawing die uses direct water cooling, providing good cooling effects.

- **Tension control**: Air tension is used for tuning, ensuring stable drawing.

- **Ease of use**: Simple threading, convenient operation, no twisting of steel wire during the drawing process, and high-quality drawn products.

- **Process flexibility**: Jump mode can be set arbitrarily to adapt to different processes.

- **Remote diagnosis**: Can be realized through Ethernet.

- **Safety**: Fully enclosed protection system with multiple protection functions for enhanced safety.

- **Control technology**: Utilizes AC frequency conversion control technology, PLC program control, and screen display for a high degree of automation.

- **Electric control system**: Employs field bus technology with all-digital control, ensuring stable and reliable operation.

- **Compatible pay-off machines**: I-wheel pay-off, duckbill pay-off, cantilever pay-off, hydraulic up-draw pay-off.

- **Compatible take-up machines**: I-wheel take-up, trunk take-up, inverted take-up, loose frame take-up.

HORIZONTAL FOUR-SHAFT WET WIRE DRAWING MACHINE specification

| product model | CL23/230 | CL23/200 | CL25/160 | CL25/130 |

| Drawing pass | 23 | 23 | 25 | 25 |

| Inlet wire diameter | ф1.4mm ~ф0.8mm | ф1.0mm ~ф0.6mm | ф0.8mm ~ ф0.5mm | ф0.25mm~ф0.1mm |

| outlet wire diameter | ф0.3mm ~ ф0.1mm | ф0.02mm ~ф0.08mm | ф0.18mm ~ф0.06mm | ф0.06mm ~ф0.03mm |

| Drawing speed | 800m/min(Max) | 800m/min(Max) | 600m/min | 800m/min |

| Main motor power | 18.5kw | 15kw | 11kw | 4kw |

| Equipment noise | ≤85dB(A) | ≤85dB(A) | ≤85dB(A) | ≤85dB(A) |