Textile Nylon Climbing Rope Cord Cordage Making Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

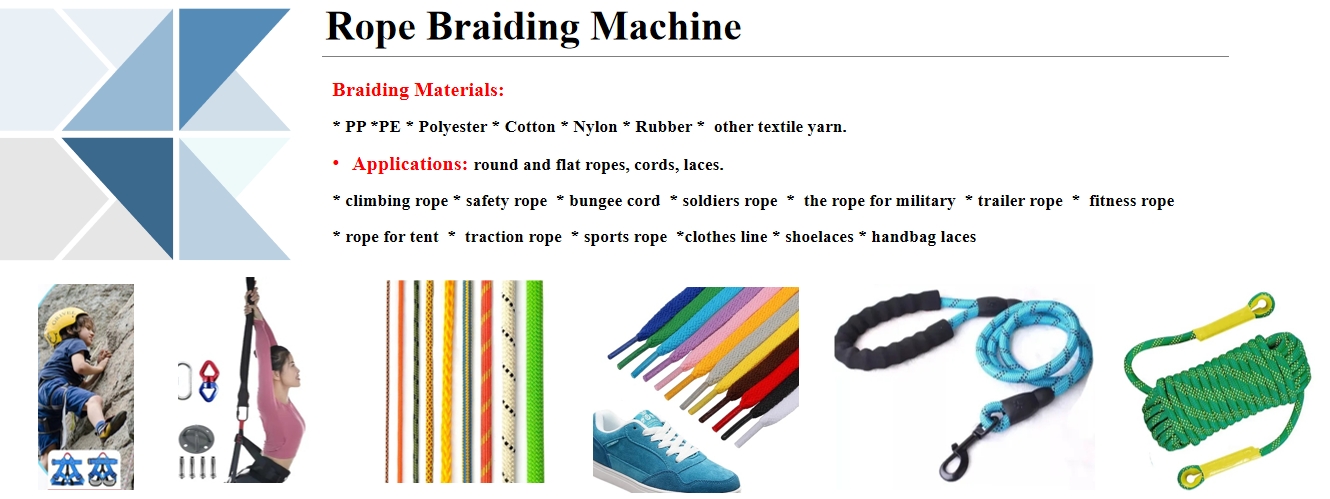

Application: * climbing rope * safety rope * bungee cord * soldiers rope * the rope for military * trailer rope * fitness rope * rope for tent * traction rope * sports rope *clothes line * shoelaces * handbag laces

Carrier Per Deck: 3-120

Textile Nylon Climbing Rope Cord Cordage Making Machine

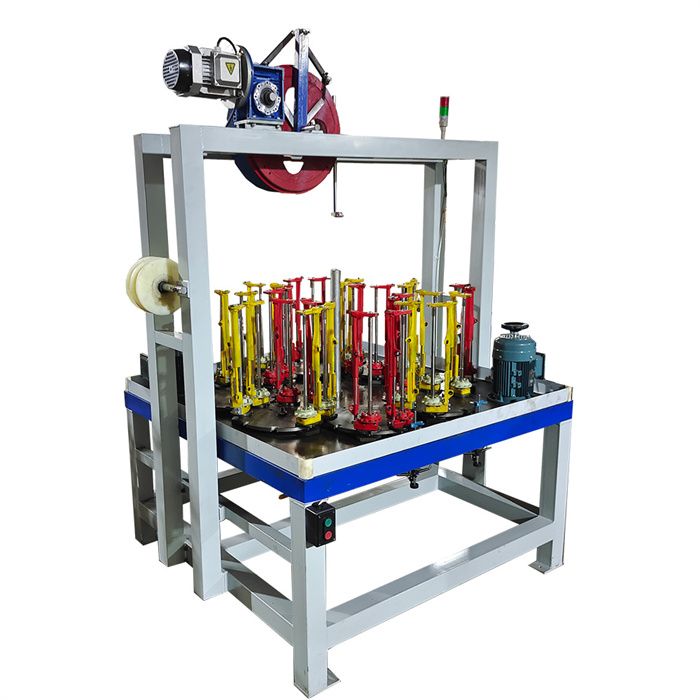

1) Reasonable structure requires minimal space, ensuring efficient use of work areas.

2 Ease of operation and maintenance simplifies the user experience.

3) While top-class parts contribute to an extended service life.

4) This machine operates with low horsepower and electricity costs, offering an economically sound choice for businesses.

5) Enhanced performance is achieved through the integration of a transducer, automatic stop unit for wire breaking, and a rolling-back unit.

6) The machine boasts a larger bobbin volume and easier tenability adjustment, enhancing its versatility.

7)Durable components and straightforward maintenance contribute to lower overall maintenance costs compared to horizontal high-speed braiding machines.

Download

Textile Nylon Climbing Rope Cord Cordage Making Machine

Product Description:

Our Textile Nylon Climbing Rope Cord Cordage Making Machine is an advanced and robust solution designed specifically for the production of high-quality nylon climbing ropes. Engineered with precision and efficiency in mind, this machine is capable of handling nylon fibers to create durable and reliable cords, meeting the stringent requirements of the climbing and outdoor adventure industries.

Product features:

Nylon Fiber Compatibility:

This machine is optimized for working with nylon fibers, ensuring the production of climbing ropes with exceptional strength, durability, and resistance to abrasion. Nylon is known for its excellent tensile strength, making it a preferred material for climbing applications.

Customizable Rope Specifications:

Users have the flexibility to customize the specifications of the climbing ropes, including diameter, length, and texture. This adaptability allows for the production of ropes tailored to specific climbing needs and industry standards.

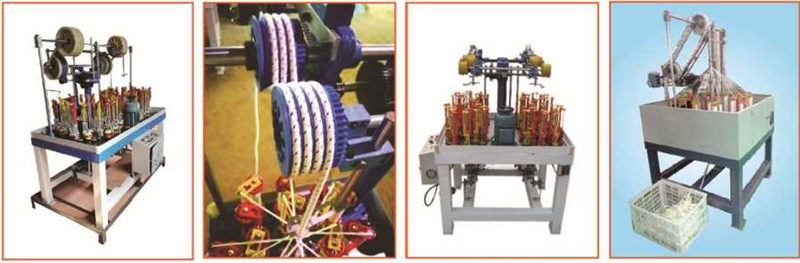

High-Speed Production:

Engineered for efficiency, the machine operates at high speeds, facilitating a significant production output. This is crucial for meeting the demands of the climbing industry where safety and reliability are paramount.

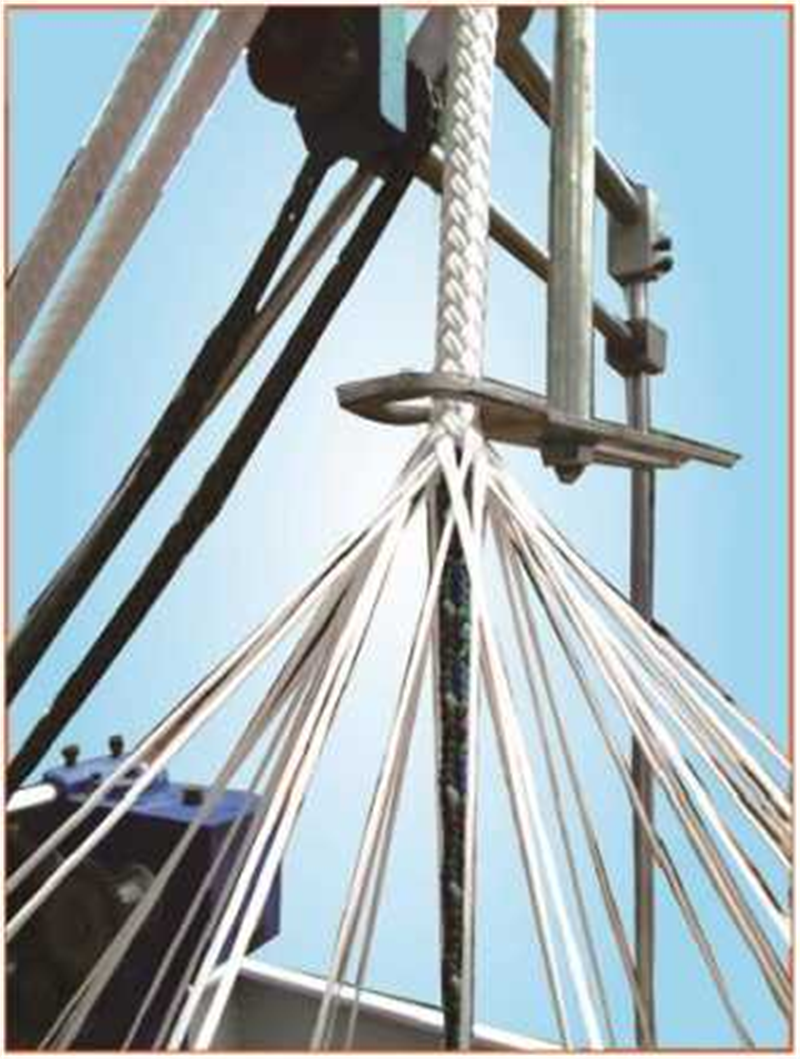

Precision Braiding Technology:

The machine incorporates advanced braiding technology to ensure precise and uniform braiding patterns. This precision is essential for maintaining the structural integrity and strength of the climbing ropes.

User-Friendly Interface:

The machine features an intuitive control panel, allowing operators to easily set and monitor parameters. This user-friendly design reduces the learning curve for operators, contributing to a seamless production process.

Durable Construction:

Built with high-quality materials and precision engineering, the machine is robust and durable. This ensures a long operational life, reducing maintenance requirements and overall cost of ownership.

Safety Features:

Safety is a priority. The machine incorporates safety features such as emergency stop mechanisms and safety interlocks to create a secure working environment for operators.

Main feature:

1) Reasonable structure requires minimal space, ensuring efficient use of work areas.

2) Ease of operation and maintenance simplifies the user experience.

3) While top-class parts contribute to an extended service life.

4) This machine operates with low horsepower and electricity costs, offering an economically sound choice for businesses.

5) Enhanced performance is achieved through the integration of a transducer, automatic stop unit for wire breaking, and a rolling-back unit.

6) During the braiding process, the absence of oil spraying makes it particularly suitable for transparent materials, preserving their integrity and appearance.

7) The machine boasts a larger bobbin volume and easier tenability adjustment, enhancing its versatility.

8) Durable components and straightforward maintenance contribute to lower overall maintenance costs compared to horizontal high-speed braiding machines.

9) The vast application area, including the capability for hybrid braiding wire and chemical fiber, underscores its adaptability across diverse industries.

10) A notable feature is the option for a fully enclosed safety hood, reducing noise levels by 10-15 db. This not only addresses environmental considerations but also creates a more comfortable and safer working environment for operators.

In summary, the rope braiding machine combines a reasonable structure, user-friendly operation, and top-quality components to offer a reliable and efficient solution for various braiding needs. Its versatility, durability, and noise reduction features position it as a valuable asset in different industrial settings, ensuring optimal performance and cost-effectiveness.

Specifications:

Textile Nylon Climbing Rope Cord Cordage Making Machine

Textile Machinery Nylon Rope Making Machine,Climbing Rope braiding machine,Cord Cordage Braiding Machines

| Spindle | Head number | Pitch size(mm) | Braiding type | Bobbin size(mm) | Braiding range(mm) | Speed ( RPM ) |

| 8 | 4 | 130 | flat | Φ47*141/175*195 | 0.5*0.5—2*2 | 205 |

| 12 | 2 | 130 | round | Φ70*210/Φ65-210 | Φ5-10 | 205 |

| 16 | 2 | 130 | round | Φ70*210/Φ65-210 | Φ6-12 | 205 |

| 24 | 2 | 130 | round | Φ70*210/Φ65-210 | Φ5-20 | 205 |

| 24 | 1 | 130 | round | Φ70*210/Φ65-210 | Φ5-20 | 205 |

| 32 | 1 | 130 | round | Φ70*210/Φ65-210 | Φ10-35 | 205 |

| 48 | 1 | 130 | round | Φ70*210/Φ65-210 | Φ20-50 | 205 |

Textile Nylon Climbing Rope Cord Cordage Making Machine

Textile Machinery Nylon Rope Making Machine,Climbing Rope braiding machine,Cord Cordage Braiding Machines

Applications:

This model braiding machines Suitable for the braiding of :

climbing cord, safety rope, bungee cord, solider cord , the rope for military , trailer rope, fitness rope, rope or tent, traction rope, sport rope, fire rope, bungee cord. mountaineering ropes

shoelace, drawing string, hollow cord, elastic cord, and decorative ribbons and elastic bands, clothes ropes, security lines and pet neck line, Sports &Leisure accessory , fish thread.

Braiding material:

Cotton, PP, PE,Fiber glass, nylon, Carbon Fiber,PET and other composite materials.

Please do not hesitate to contact us, Free samples are available, We will reply you in 24 hours, Welcome for your any OEM customization orders!Invest in our Textile Nylon Climbing Rope Cord Cordage Making Machine for a reliable and efficient solution in producing top-quality nylon climbing ropes for the demanding requirements of the climbing and outdoor industries.