Steel Wire SS Wire Sleeve Braiding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: sanitary, cable, high-pressure hose industries,

Carrier Per Deck: 16,24,32

Braided Hose OD: 16,24,32mm

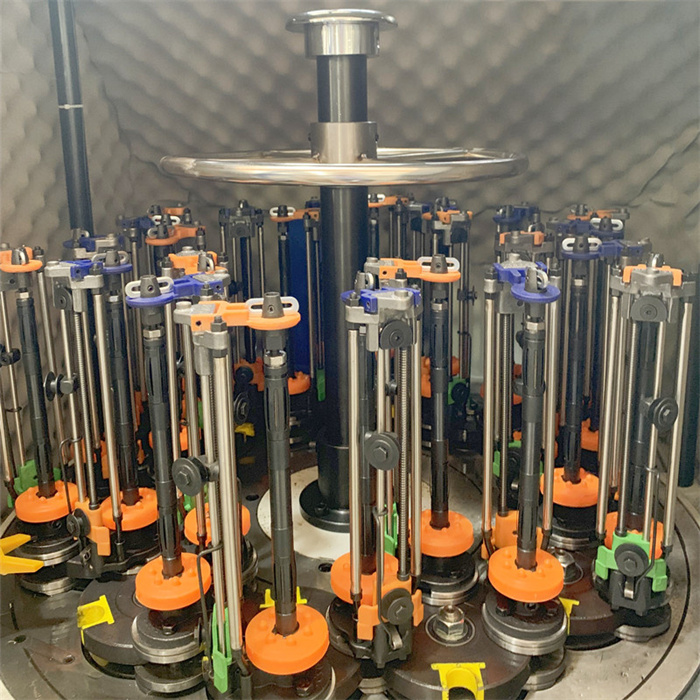

Greenland Benfa technology Steel Wire SS Wire Sleeve Braiding Machine

1, excellent quality and service. good price.Top 1 hose braiding machine manufacturer.

2, High production capacity,fast braiding speed.

3, Automatic and easy operation.

4, 25-year-old hose braiding machine design and production, with unique style. Also welcome customized.

5, Different specifications to meet different braided diameters from 16,20,32,36,48mm.

Download

Greenland Benfa technology Steel Wire SS Wire Sleeve Braiding Machine

Product Description:

A steel wire or stainless steel (SS) wire sleeve braiding machine is used for the production of hoses or cables that require additional reinforcement through the braiding of steel wires or stainless steel wires around the core material. This type of braiding adds strength, durability, and resistance to external factors such as abrasion or pressure.

Product features:

Material Compatibility:

Ensure that the machine is designed to handle steel wires or stainless steel wires as the braiding material. The choice between steel and stainless steel may depend on the specific requirements of the application, including factors such as corrosion resistance.

Wire Diameter and Type:

The machine should be adjustable to accommodate different wire diameters and types. Different applications may require different thicknesses and materials for the braiding wires.

Braiding Patterns:

Depending on the application, you may need different braiding patterns for optimal strength and flexibility. Ensure that the machine supports the required patterns.

Core Material Compatibility:

Consider the types of core materials (hoses or cables) that will be braided. The machine should be compatible with the materials you are working with.

Adjustability:

The machine should be easily adjustable to accommodate various sizes of hoses or cables. This includes adjustments for both core and braiding material.

Automation:

Automation features can enhance efficiency and consistency in the braiding process. Look for machines with automated controls and settings.

Speed and Production Output:

Consider the production speed of the machine and whether it meets your production requirements. High-speed machines are beneficial for large-scale production.

Tension Control:

Tension control mechanisms are crucial for maintaining uniform braiding quality. Ensure that the machine has effective tension control features.

User-Friendly Interface:

An intuitive and user-friendly interface can simplify operation and reduce the learning curve for operators.

Quality Control:

Look for features that ensure the quality of the braided product, including real-time monitoring and quality control mechanisms.

Maintenance and Support:

Check for the availability of maintenance support and spare parts. Regular maintenance is essential to keep the machine in optimal condition.

Compliance with Standards:

Ensure that the machine complies with relevant industry standards and regulations, especially if the braided products are intended for specific applications or industries.

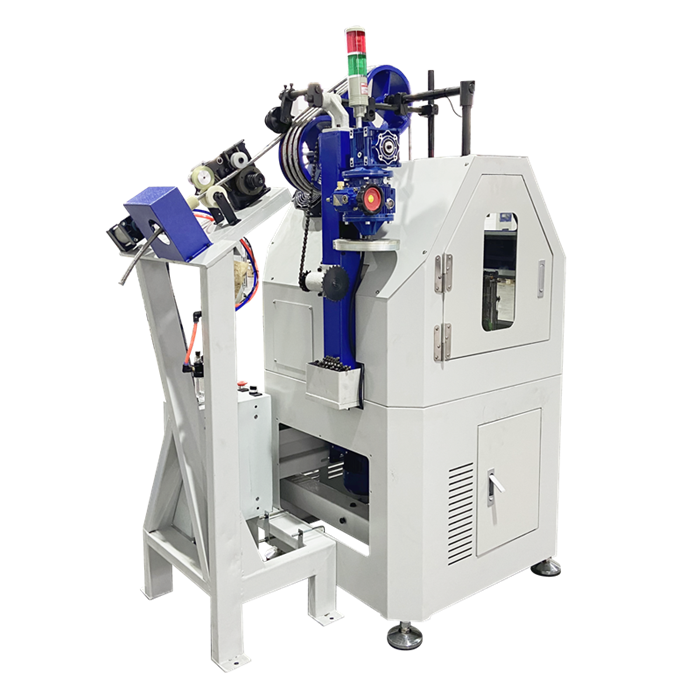

SS wire sleeve braiding machine

steel wire braiding machine

SS wire sleeve braiding machine

114L:with horn gear OD114mm,suitable for bobbin OD ≤ 58mm

BFB-114L series vertical CNC automatic braider are widely used in sanitary industry, cable industry and high pressure hose industry ,

suitable for stainless steel wire cotton yarn, aramid fiber ,carbon fiber and other braiding materials.

Main Features

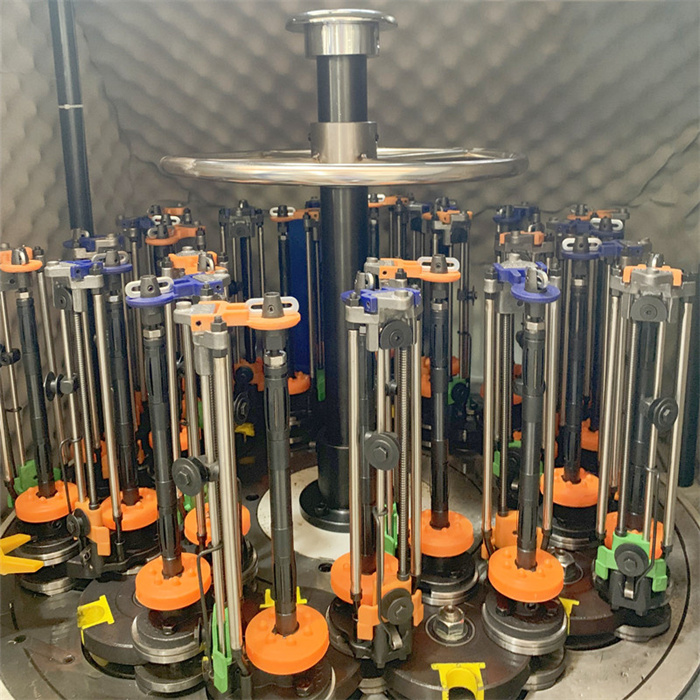

Oil bath lubrication system are used, stable carrier tension, easy to maintain.

Patented in house designed plate with guide, prolong machine life

Low noise , tested noises 78dB for enclosed braider, noise and shocking absorbing design.

Carrier rpm is 5% higher than the horizontal model carrier rpm can reach up to 310rpm , high productivity.

Machine stops & alarms when broken wire, out of wire, out of tubing or rubber sheet detected, ensure machine runs safely.

Custom design available per request.

Specifications:

Greenland Benfa technology hose braiding machine 114 series Automatic Hose Braiding Machine has different specifications to meet your different demand

braiding machine diy,braiding machines,braiding wire machine,braids makers machines

Type | carrier per deck | carrier speed RPM | braiding machine power | haul off motor power | braiding pitch set up | carrier tension | braided hose OD | weight |

| BFB16L-1148 | 16 | 55rpm(max) | 0.75KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤16mm | 280kg | |

| BFB24L-114AF | 24 | 45rpm(max) | 1.1KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 305kg | |

| BFB24L-114B | 24 | 45rpm(max) | 1.1KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 305kg | |

| BFB24L-114B1 | 24 | 45rpm(max) | 1.1KW | mechanical variable speed drive | 0.4kg-5.Okg | ≤24mm | 305kg | |

| BFB24L-114B Ⅱ | 24 | 45rpm(max) | 1.1KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 305kg | |

| BFB24L-114BF | 24 | 45rpm(max) | 1.1KW | mechanical variable speed drive | 0.4kg-5.Okg | ≤24mm | 305kg | |

| BFB24L-114BS | 24 | 45rpm(max) | 1.5KW-2 | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 600kg | |

| BFB24L-114C | 24 | 45rpm(max) | 1.1KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤24mm | 305kg |

| BFB24L-114CF | 24 | 45rpm(max) | 1.1KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤24mm | 305kg |

| BFB24L-114D | 24 | 52rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 330kg | |

| BFB24L-114Dl | 24 | 40rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 330kg | |

| BFB32L-114B | 32 | 35rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤32mm | 400kg | |

| BFB36L-114B | 36 | 29rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 450kg | |

| BFB36L-114BI | 36 | 29rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 450kg | |

| BFB36L-114BⅡI | 36 | 29rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 450kg | |

| BFB36L-114C | 36 | 29rpm(max) | 1.5KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤36mm | 450kg |

| BFB36L-114CF | 36 | 29rpm(max) | 1.5KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤36mm | 450kg |

| BFB36L-114D | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 475kg | |

| BFB36L-114DI | 36 | 29rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 475kg | |

| BFB36L-114DⅡ | 36 | 29rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 475kg | |

| BFB48L-114AF | 48 | 20rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤48mm | 128Okg | |

| BFB48L-114B | 48 | 20rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤48mm | 1280kg | |

| BFB48L-114CF | 48 | 20rpm(max) | 2.2KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤48mm | 1280kg |

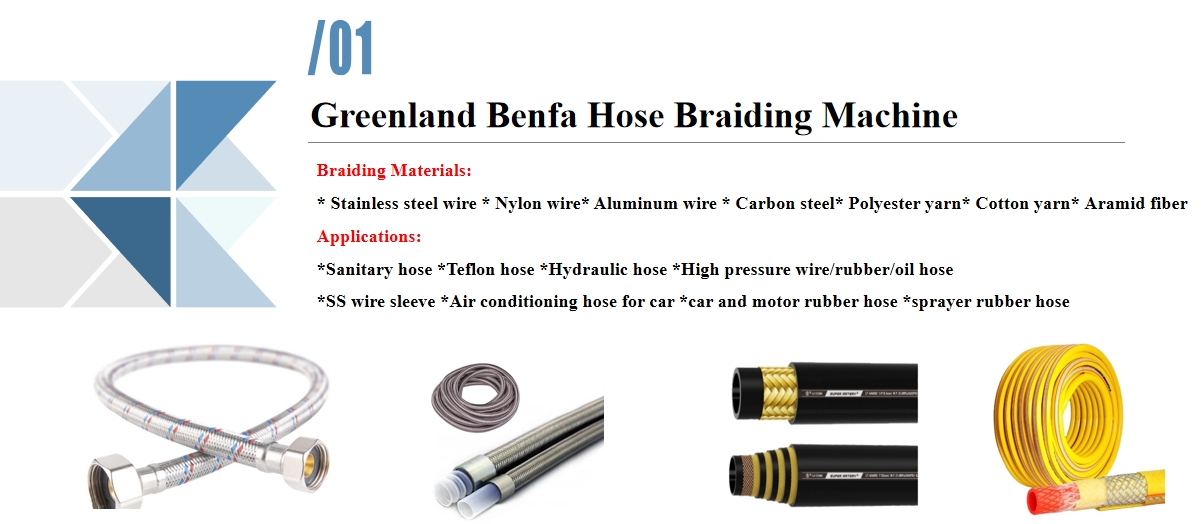

Applications:

Greenland Benfa technology hose braiding machine widely use in different industries,such as sanitary hose , high pressure wire/rubber/oil hose, Teflon hose,

SS wire sleeve, air conditioning hose , car and motor rubber hose, sprayer rubber hose and so on.

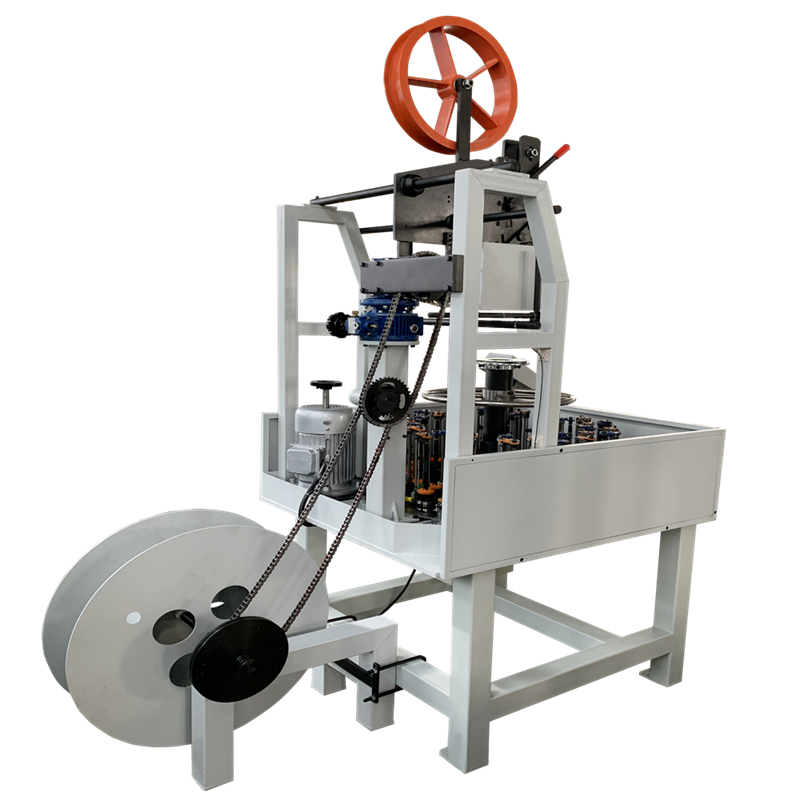

Product Detail:

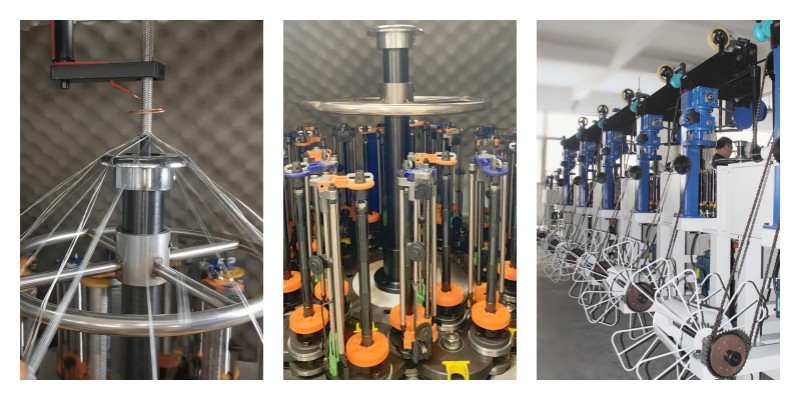

Greenland Benfa technology hose braiding machine details as below photos: