Reusuable Hydraulic Hose Assembly Equipment

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Greenland Benfa technology reusuable Hydraulic Hose Assembly Equipment

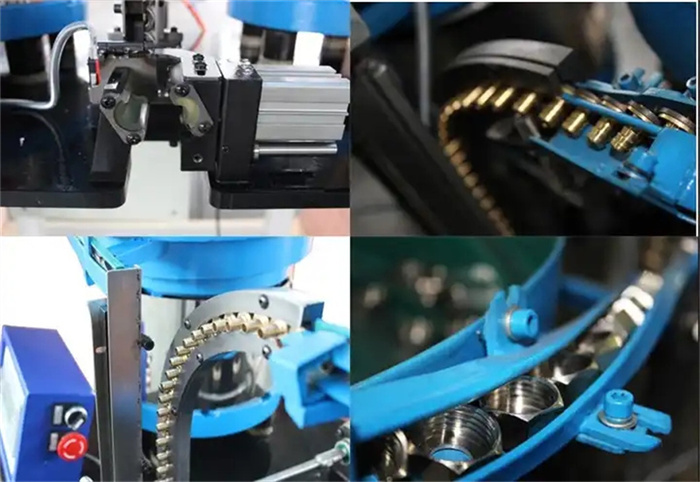

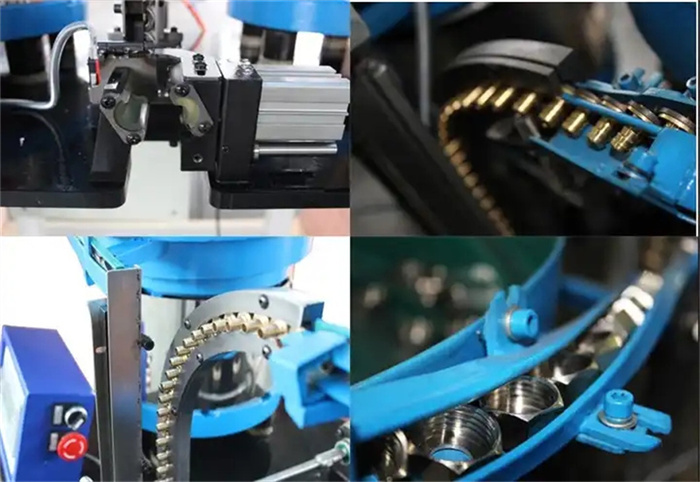

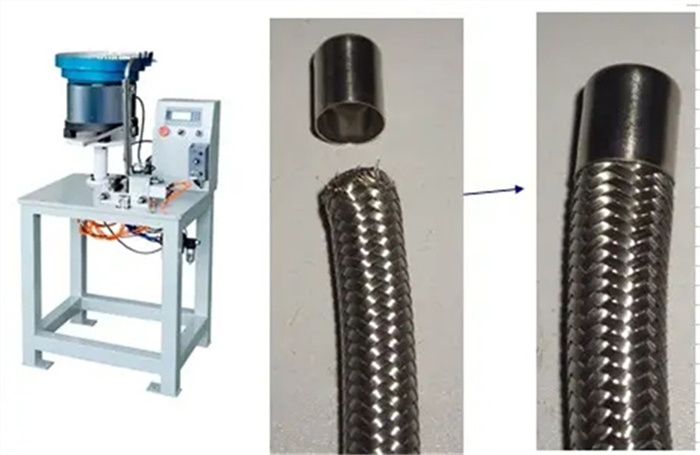

1) reusuable assembly hose machine,auto assemble machine worm drive hose clamp,wind cool the hydraulic oil,

stable pressure.

2) Motor blue provided, Crimper good looking, crimper dimension stable and controllable。

3) hydraulic hose assembly equipment steady pressure and easy to adjust.

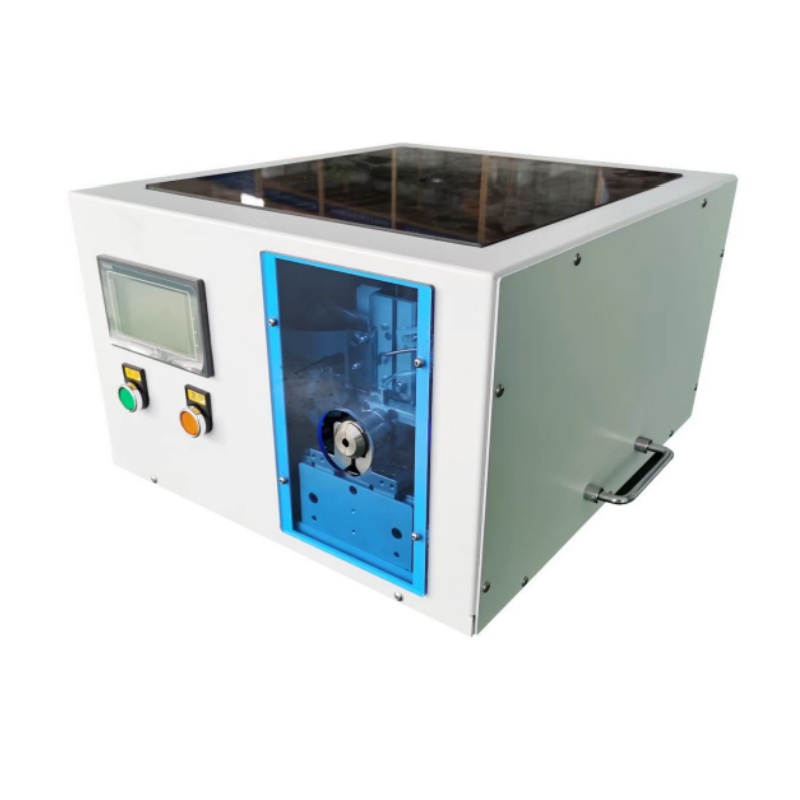

4) hydraulic hose assembly machine, Digital display, show the pressure, production and temperature

5) Hose assembly crimping machine, High automatic and speed, adopt touch braking way。

Greenland Benfa technology Reusuable Hydraulic Hose Assembly Equipment

hydraulic hose assembly equipment,hydraulic hose assembly machine,reusuable assembly hose machine

Main feature:

Greenland Benfa technology Reusuable Hydraulic Hose Assembly Equipment

hydraulic hose assembly equipment,hydraulic hose assembly machine,reusuable assembly hose machine

Steady pressure and easy to adjust.

High automatic and speed, adopt touch braking way。

Wind cool the hydraulic oil, stable pressure.

Crimper good looking, crimper dimension stable and controllable。

Digital display, show the pressure, production and temperature

Specifications:

Greenland Benfa technology Auto Rubber Hose Crimper Assemble Machine

Assembly hose machine,auto assemble machine worm drive hose clamp,rubber hose assembly crimper machine

Type | Voltage | Power | Air pressure | Working frequency | Measurement | Weight | Function |

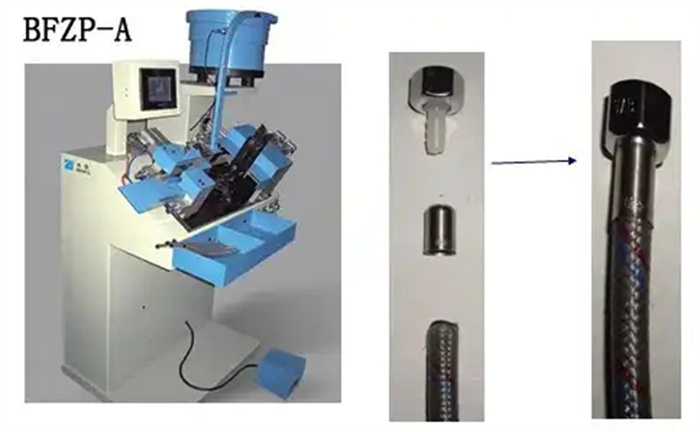

| BFZT-A | 220V | 500w | 0.3-0.5MPa | 75root/min | 800×600×1400mm | 100kg | Assemble sleeve |

| BFZX-A | 220V | 1000w | 0.3-0.5MPa | 80root/min | 900×780×1200mm | 170kg | Assemble core & nut |

| BFZP-X | 220V | 1500w | 0.3-0.5MPa | 45root/min | 1200×1100×1450mm | 420kg | Assemble sleeve & core & nut |

| BFZP-X1 | 220V | 1500w | 0.3-0.5MPa | 46root/min | 1200x1100×1450mm | 420kg | Assemble sleeve & core & nut |

| BFZP-X2 | 220V | 1500w | 0.3-0.5MPa | 47root/min | 1200×1100×1450mm | 420kg | Assemble sleeve & core & nut |

| BFZP-X3 | 220V | 3000w | 0.3-0.5MPa | 12root/min | 1800x1065×1800mm | 750kg | Assemble sleeve & core & nut |

| BFZP-X4 | 220V | 3000w | 0.3-0.5MPa | 12root/min | 2000×1150×1871mm | 800kg | Assemble sleeve & core & nut |

| BFZP-X5 | 220V | 6000w | 0.3-0.5MPa | 12root/min | 2000x1734x1700mm | 1300kg | Assemble sleeve & core & crimpe |

| BFZP-B | 220V | 1500w | 0.3-0.5MPa | 45root/min | 1200× 1100×1450mm | 210kg | Assemble sleeve & core & nut |

| BFZP-C | 220V | 500W | 0.3-0.5MPa | 45root/min | 68O×520×109Bmm | 141kg | Assemble sleeve & core & nut |

| BFZP-D | 220V | 0.3-0.5MPa | 25root/min | 412×405×312mm | 35kg | Assemble sleeve & core & nut | |

| BFZP-D1 | 220V | 0.3-0.5MPa | 25root/min | 720×500× 450mm | 57kg | Assemble sleeve & core & nut | |

| BFJYZX-A | 220V | 0.3-0.5MPa | 25root/min | 730×520×747mm | 48kg | Assemble sleeve & core & nut | |

| BFCX-A | 220V | 0.3-0.5MPa | 25root/min | 326×240×260mm | 15kg | Assemble sleeve & core & nut | |

| BFOz-A | 220V | 500W | 0.3-0.5MPa | 35root/min | 2000x1500×1808mm | 1000kg | Assemble washer |

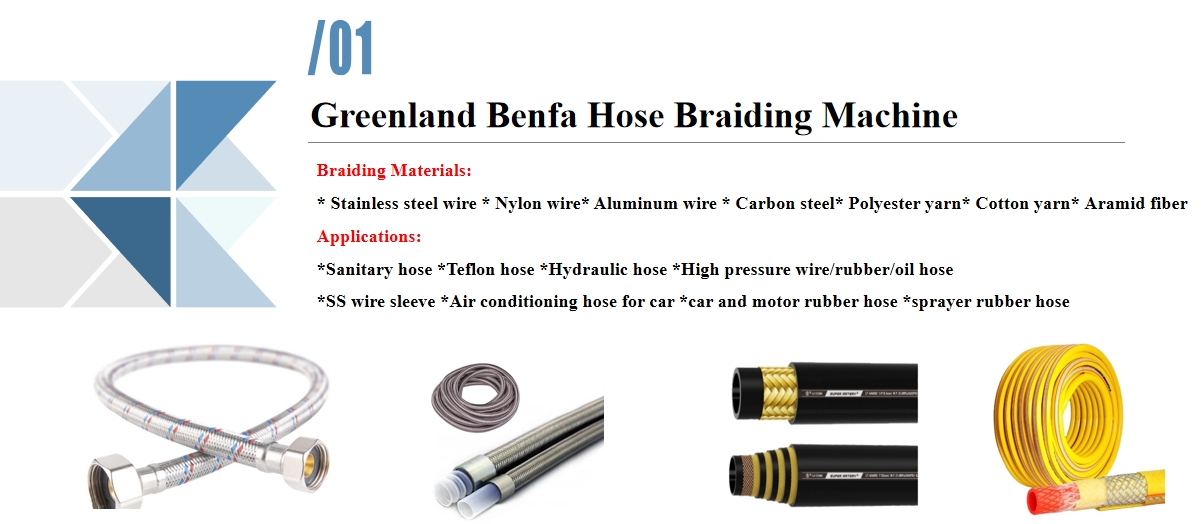

Applications:

Greenland Benfa technology hose braiding machine widely use in different industries,such as sanitary hose , high pressure wire/rubber/oil hose, Teflon hose,

SS wire sleeve, air conditioning hose , car and motor rubber hose, sprayer rubber hose and so on.

Description:

Greenland Benfa's Reusable Hydraulic Hose Assembly Equipment signifies a cutting-edge solution in hydraulic hose assembly technology,

embodying a suite of exceptional features that redefine industry standards.

At the forefront of its capabilities is the machine's prowess in ensuring a consistent and controllable pressure during the hydraulic

hose assembly process. This is coupled with effortless adjustability, empowering operators with precise control over assembly parameters.

The streamlined workflow is enhanced by the machine's high-speed operation, employing a touch braking mechanism for seamless automation.

This not only elevates productivity but also ensures a smooth and controlled assembly process.

An innovative element is the incorporation of a wind cooling system, a feature crucial for maintaining the stability of hydraulic oil.

This ensures a sustained and consistent pressure throughout the assembly operation, contributing not only to optimal performance

but also extending the operational life of the equipment.

Precision and design excellence are hallmarks of the crimper, boasting an aesthetically pleasing appearance while maintaining stable

and controllable dimensions. This precision is paramount for meeting stringent quality standards, ultimately ensuring the reliability

of the final hydraulic hose assembly.

The equipment's interface is elevated with a digital display, allowing operators to monitor key parameters such as pressure, production details,

and temperature in real-time. This not only enhances overall operational transparency but also contributes to greater efficiency in managing the assembly process.

In conclusion, Greenland Benfa's Reusable Hydraulic Hose Assembly Equipment stands as a beacon of reliability and innovation in hydraulic hose assembly.

The combination of consistent pressure control, high-speed operation, cooling ingenuity, precision design, and digital monitoring firmly establishes it

at the forefront of technology, meeting the evolving needs of modern hydraulic system manufacturing.