Metal Braiding Motor Hose Braiding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: sanitary, cable,car and motor hose,high-pressure hose industries,

Carrier Per Deck: 16,20,32,36,48

Braided Hose OD: 16,20,32,36,48mm

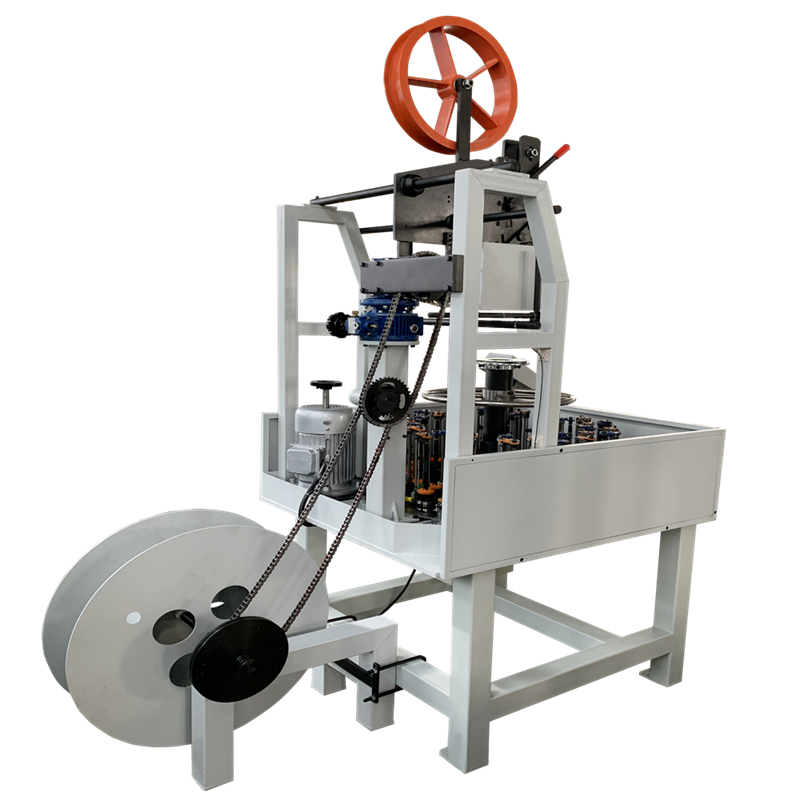

Greenland Benfa technology Metal Braiding Motor Hose Braiding Machine

hose braiding machine,metal braiding machine,motor hose braiding machine.

1, Top 1 hose braiding machine manufacturer, excellent quality and service. good price.

2, Fast braiding speed, High production capacity.

3, Automatic and easy operation.

4, Different specifications to meet different braided diameters from 16,20,32,36,48mm.

5, 25-year-old hose braiding machine design and production, with unique style. Also welcome customized.

Download

Greenland Benfa technology Metal Braiding Motor Hose Braiding Machine

hose braiding machine,metal braiding machine,motor hose braiding machine.

Main feature:

3, High automatic extent broken ,empty bobbin or no tube automatic machine self-closed.

4, Adopt adjustable speed to accommodate pitch. don't need to change gear.

Specifications:

Greenland Benfa technology Metal Braiding Motor Hose Braiding Machine 140 series has different specifications.

hose braiding machine,metal braiding machine,motor hose braiding machine.

| Type | carrier per deck | carrier speed [RPM] | braiding machine power | haul off motor power | braiding pitch set up | carrier tension | braided hose OD | Weight |

| BFB16L-140CFS | 16 | 55rpm(max) | 1.5KW*2 | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤16mm | 300kg |

| BFB20L_140B | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L_140B II | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L-140BF | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L-140CF | 20 | 44rpm(max) | 1.5KW | 0.55Kw | electronic parameter set | 0.4kg-5.0kg | ≤20mm | 350kg |

| BFB24L-140CFS | 24 | 42rpm(max) | 1.5KW*2 | 0.55KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 580kg |

| BFB24L-140AF | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140AF II | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140B | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140B II | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140BF | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140CF | 24 | 42rpm(max) | 1.5KW | 0.55KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 380kg |

| BFB20L+24L-140CFS I | 24 | 37rpm(max) | 1.5KW*2 | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 700kg |

| BFB24L+24L-140CFS I | 24 | 37rpm(max) | 1.5KW*2 | 0.75Kw | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 700kg |

| BFB24L-140CS | 24 | 37rpm(max) | 1.5KW*2 | 0.55Kw | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 630kg |

| BFB24L-140D | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140DI | 24 | 37rpm(max) | 1.5xW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB32L-140A | 32 | 28rpm(max) | 2 2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤32mm | 430kg | |

| BFB32-140B | 32 | 28rpm(max) | 2 2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤32mm | 430kg | |

| BFB32L-140CF | 32 | 28rpm(max) | 2.2KW | 0.75KW | ectronic pararmeter set | 0.4kg-5.0kg | ≤32mm | 430kg |

| BFB36L-140AF | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140B | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140BF | 36 | 29rpm(max) | 2 2xw | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140CF | 36 | 29rpm(max) | 2.2KW | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤36mm | 520kg |

| BFB36L-140D | 36 | 29rpm(max) | 3.0KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB48L-140B | 48 | 25rpm(max) | 3.0KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤48mm | 550kg | |

| BFB48L-140CF | 48 | 25rpm(max) | 3.0Kw | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤48mm | 550kg |

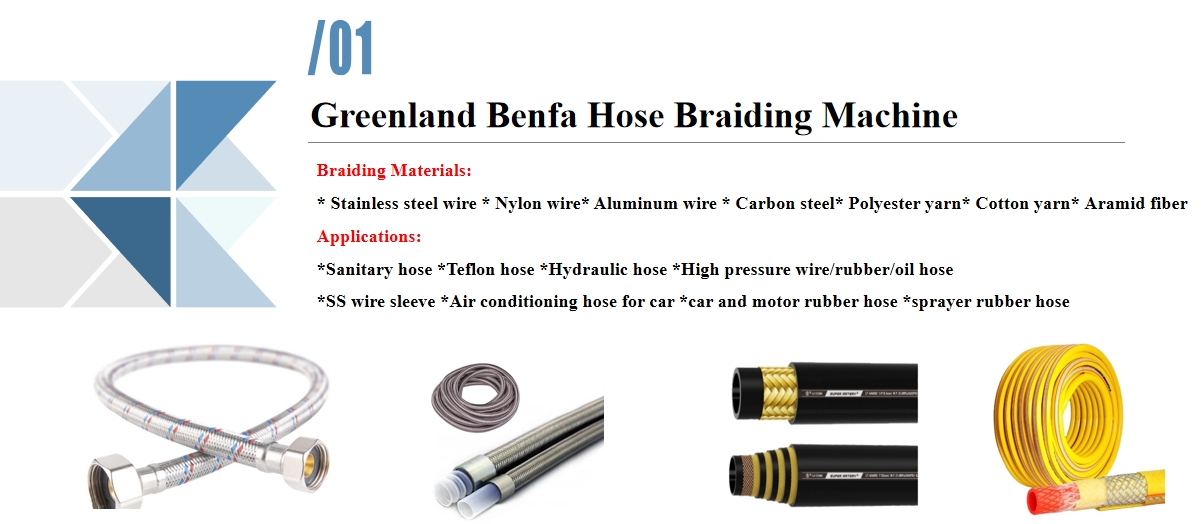

Applications:

Greenland Benfa hose braiding machine widely use in different industries,such as sanitary hose , high pressure wire/rubber/oil hose, Teflon hose,

SS wire sleeve, air conditioning hose , car and motor rubber hose, sprayer rubber hose and so on.

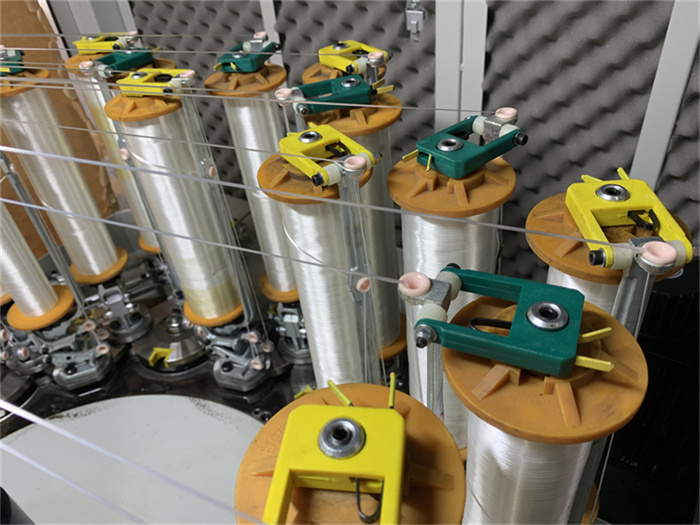

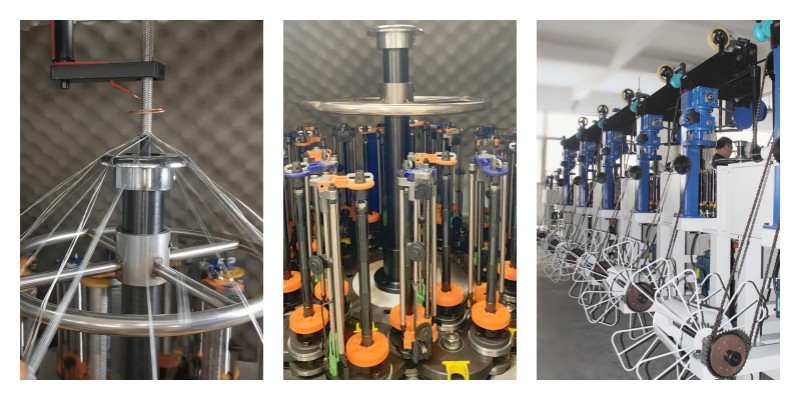

Product Detail:

Greenland Benfa technology hose braiding machine details as below photos:

Description:

Greenland Benfa technology hose braiding machine140L:with horn gear OD140mm,suitable for bobbin OD ≤ 82mm

Greenland Benfa technology Metal Braiding Motor Hose Braiding Machine

hose braiding machine,metal braiding machine,motor hose braiding machine.

carriers per deck | bobbin dimension |

8-96 | 80×28×277mm |

carrier speed [RPM] | bobbin capacity |

20-55 | 130 cm3-360 cm3 |

**Greenland Benfa's 140L Series Vertical Hose Braiding Machine:**

The Greenland Benfa Technology Metal Braiding Motor Hose Braiding Machine stands as a premier solution in the realm of hose manufacturing,

embodying excellence as the top-rated hose braiding machine manufacturer. Renowned for its unwavering commitment to quality, service,

and competitive pricing, this machine represents a pinnacle in the industry.

At the core of Greenland Benfa's offering is its exceptional quality and service, establishing it as the leading hose braiding machine manufacturer.

The company's dedication to delivering top-tier products and unparalleled support ensures that clients receive not only a machine but a reliable

and enduring solution for their manufacturing needs.

A key highlight of this machine is its remarkable braiding speed, contributing to a high production capacity. In a landscape where efficiency is paramount,

this feature positions the Greenland Benfa machine as a strategic asset, meeting the demands of a dynamic market that values speed and productivity.

The automation capabilities of the machine elevate its operational efficiency. It exhibits a high degree of automation, responding automatically to issuessuch as broken wires, empty bobbins, or the absence of tubing. This self-closing mechanism enhances safety protocols and ensures a seamless,

uninterrupted production process.

Adding a layer of flexibility to its operation, the machine adopts adjustable speed without the need for gear changes. This adaptability is particularly valuable

when accommodating different pitch requirements, providing a level of operational versatility that aligns with the diverse needs of the industry.

Versatility is a defining characteristic of the Greenland Benfa machine, as it caters to different braided diameters. With specifications covering diameters ranging

from 16mm to 48mm, the machine is equipped to handle a variety of applications. This broad range of capabilities positions it as a versatile and adaptable solution

for industries with diverse production requirements.

A testament to its enduring success, Greenland Benfa Technology boasts a 25-year legacy in hose braiding machine design and production. This extensive experience

is reflected in the machine's unique style, marrying innovation with proven practices. Furthermore, the company is open to customization,

allowing clients to tailor the machine to their specific requirements.

In conclusion, the Greenland Benfa Technology Metal Braiding Motor Hose Braiding Machine emerges as a comprehensive and leading-edge solution

for hose manufacturing. With its top-tier manufacturing status, impressive features including fast braiding speed, automation, adjustable speed, and adaptability to various specifications,

this machine exemplifies excellence in the hose braiding machinery landscape. It not only meets industry standards but sets them, providing clients with a reliable and efficient

tool for their production needs.