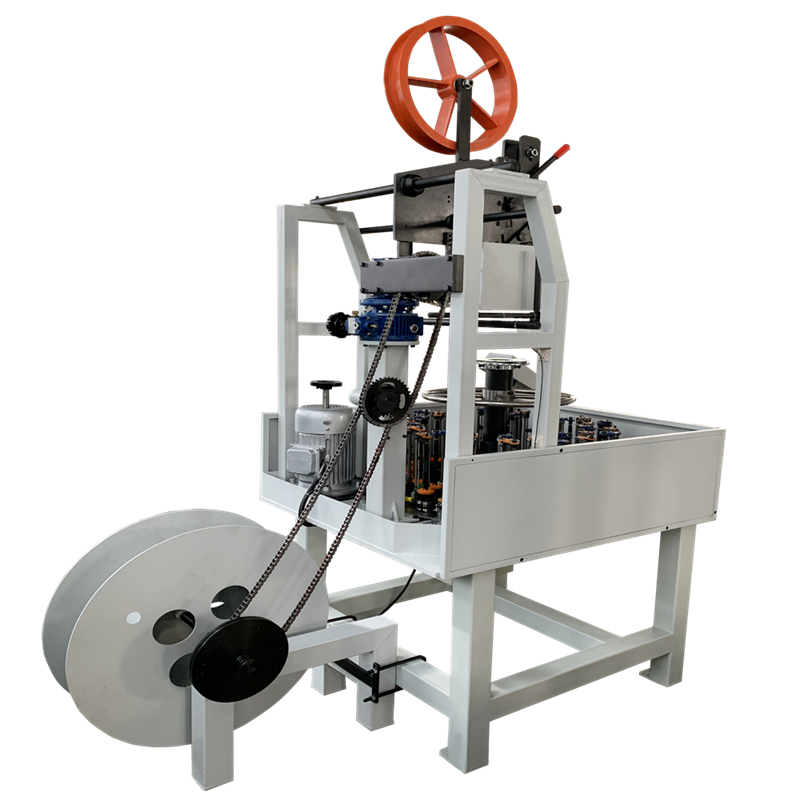

High Pressure Oil Rubber Wire Hose Braiding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: steel wire braided high pressure rubber tube ,steel wire braided sleeve , braided corrugated tube , high strength wire braided tube. Big diameter cable brake hose ,air conditioner hose

Carrier Per Deck: 16,20,24,28,32,36,48,64

Braided Hose OD: 16,20,24,28,32,36,55,140mm

Greenland Benfa techology High Pressure Oil Rubber Wire Hose Braiding Machine

1, Suitable for rigid tube and big diameter tube.Big diameter cable brake hose ,air conditioner hose

2, CNC controlled.

3, Fast braiding speed

4, Machine stops & alarms when broken wire.

Download

Greenland Benfa techology High Pressure Oil Rubber Wire Hose Braiding Machine

Product Description:

A high-pressure oil rubber wire hose braiding machine is a specialized piece of equipment designed for manufacturing high-pressure hoses with reinforcement through wire braiding. These hoses are commonly used in applications where they need to withstand high-pressure conditions, such as in hydraulic systems.

Product features:

Wire Braiding Capability:

The machine should be specifically designed for braiding wire around rubber hoses. This wire reinforcement enhances the hose's strength and ability to withstand high-pressure conditions.

High-Pressure Applications:

Ensure that the machine is suitable for manufacturing hoses intended for high-pressure applications, such as hydraulic systems. This involves using materials that can withstand pressure and ensuring the integrity of the braiding process.

Adjustability:

The machine should be adjustable to accommodate different hose diameters, lengths, and wire thicknesses. This adaptability is crucial for meeting diverse production requirements.

Braiding Patterns:

Consider the braiding patterns supported by the machine. The choice of braiding pattern can influence the overall strength and flexibility of the hose.

Core Material Compatibility:

Check that the machine is compatible with the core material (rubber hose) you intend to use. The machine should handle different rubber compounds effectively.

Automation:

Look for automation features, such as programmable controls and sensors, to enhance efficiency and reduce manual intervention. Automation can contribute to consistent braiding quality.

Speed and Production Output:

Consider the production speed and output capacity of the machine. High-speed machines are beneficial for large-scale production of high-pressure hoses.

Tension Control:

Effective tension control mechanisms are crucial for maintaining uniform braiding quality. The machine should provide control over the tension of the wire during the braiding process.

User-Friendly Interface:

An intuitive interface facilitates ease of operation. A user-friendly control panel is important for efficient machine operation.

Quality Control:

Features that enable real-time monitoring and quality control can contribute to the production of high-quality, reliable hoses.

Maintenance and Support:

Check for the availability of maintenance support and spare parts. Regular maintenance is essential to keep the machine running smoothly, especially in high-pressure applications.

Compliance with Standards:

Ensure that the machine complies with relevant industry standards and regulations for high-pressure hose manufacturing.

FB-200W series horizontal braider is suitable for soft and hard core big diameter high strength epdm tube ,widely used in the manufacturing of steel wire braided high pressure rubber tube ,steel wire braided sleeve , braided corrugated tube , high strength wire braided tube. Big diameter cable brake hose ,air conditioner hose ,etc., suitable for the braiding material such as stainless steel wire, steel wire ,alloy wire cotton yarn aramid yarn and other metallic wire and composite yarn .

Main Features

Fast braiding speed ,more suitable for rigid tube and big diameter tube.

Various active and passive methods such as noise absorbing, isolating, shocking absorbing material, etc.

Patented In house designed plate with guide, improve productivity and prolong machine life.

Machine stops & alarms when broken wire, out of wire out of tubing or rubber sheet detected, ensure machine runs safely.

CNC controlled, easy to adjust braid pitch (angle) & monitor status, data storage and safety protection.

Custom design available per request.

Specifications:

Greenland Benfa techology High Pressure Oil Rubber Wire Hose Braiding Machine

high pressure oil hose braiding machine,high pressure rubber hose braiding machine,high pressure wire hose braiding machine

Type | carrier per deck | carrier speed [RPM] | braiding machine power | haul off motor power | braiding pitch set up | carior tonsion | braided hose OD |

| BFB16W-200CFS | 16 | 56rpm(max) | 4.0KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤16mm |

| BFB20W-200B | 20 | 45rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤20mm |

| BFB20W-200C | 20 | 45rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤20mm |

| BFB20W-200CF | 20 | 45rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤20mm |

| BFB20W-200CFS | 20 | 45rpm(max) | 5.5KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤20mm |

| BFB20W-200BCS | 20 | 45rpm(max) | 5.5KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤20mm |

| BFB24W-200C | 24 | 37rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤24mm |

| BFB24W-200CF | 24 | 37rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤24mm |

| BFB24W-200CFS | 24 | 37rpm(max) | 5.5KW2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤24mm |

| BFB24W-200Cs | 24 | 37rpm(max) | 5.5KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤24mm |

| BFB28W-200CF | 28 | 32rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤28mm |

| BFB28W-200CFS | 28 | 32rpm(max) | 5.5KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤28mm |

| BFB32W-200B | 32 | 26rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤32mm |

| BFB36W-200C | 36 | 26rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤36mm |

| BFB36W-200CF | 36 | 26rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤36mm |

| BFB36W-200CFs | 36 | 26rpm(max) | 5.5KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤36mm |

| BFB36W-200A | 36 | 26rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤36mm |

| BFB48W-200C | 48 | 19rpm(max) | 5.5KW2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤55mm |

| BFB64W-200C | 64 | 14rpm(max) | 5.5KW*3 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤140mm |

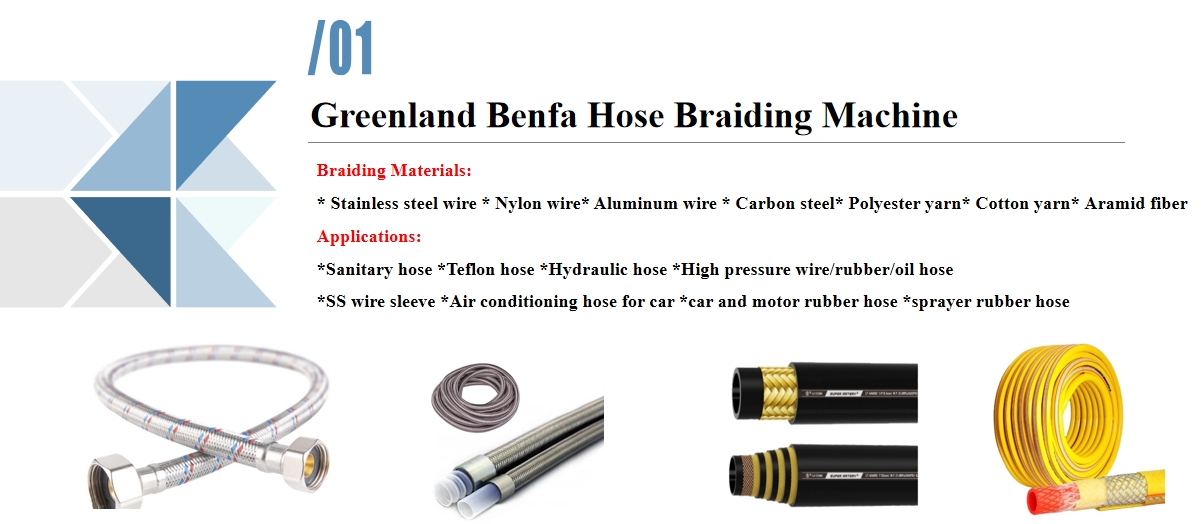

Applications:

Greenland Benfa techology Harness Braiding Machine Air Conditioner Hose Braider epdm tube braider

widely used in the manufacturing of steel wire braided high pressure rubber tube, steel wire braided sleeve, braided corrugated tube,

high strength wire braided tube. Big diameter cable brake hose ,air conditioner hose ,etc., suitable for the braiding material such as

stainless steel wire, steel wire ,alloy wire cotton yarn aramid yarn and other metallic wire and composite yarn .

Product Detail:

Greenland Benfa techology Harness Braiding Machine Air Conditioner Hose Braider epdm tube braider

details as below photos:

Please do not hesitate to contact us, We can provide detailed information based on your specific requirements and applications.

200W:with horn gear OD200mm,suitable for bobbin OD ≤ 86mm

carriers per deck | bobbin dimension |

8-96 | 80×28×277mm |

carrier speed [RPM] | bobbin capacity |

20-55 | 130 cm3-360 cm3 |