Garden Gas Hose Composite Braiding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: automobile brake tube, automobile air conditioner hose, wire & cable

Carrier Per Deck: 16,24,32,36,48

Braided Hose OD: 20,24,32,36,48mm

Garden Gas Hose Composite Braiding Machine

garden hose braiding machine,gas hose braiding machine

1, Widely used in various industries such as: automobile brake tube, automobile air conditioner hose,

wire & cable .etc

2,One worker can watch over several machines.

3,CNC controlled , easy to adjust braid pitch (angle) &monitor status.

4,Productivity = carrier pitch (RPM).

5,Automatic lubrication by Oil collecting.

Download

Garden Gas Hose Composite Braiding Machine

garden hose braiding machine,gas hose braiding machine

garden hose braiding machine

gas hose braiding machine

Main feature:

One worker can watch over several machines, machine stops & alarms when broken wire, out of wire,

out of tubing or rubber sheet detected.

CNC controlled , easy to adjust braid pitch (angle) &monitor status, data storage and safety protection.

Productivity = carrier pitch (RPM) braid pitch(mm/min) ,maximum carrier rpm reaches 50rpm.

Good outer look, professional industry design, patented outer look design.

Safe & environmental friendly , low noise , tested noises 78dB for enclosed braider.

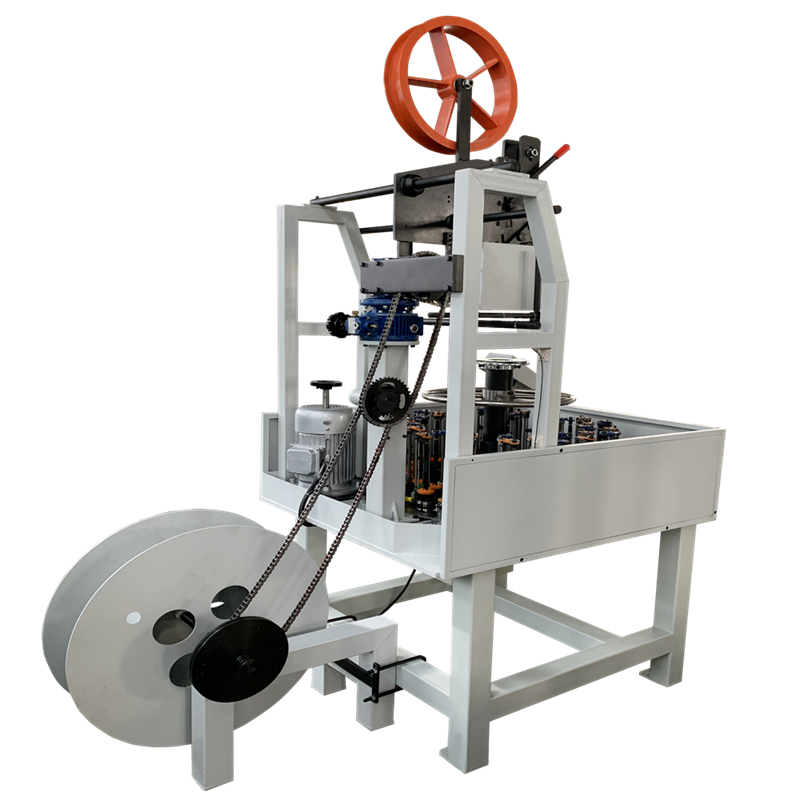

Automatic lubrication by Oil collecting circulating periodical automatic lubrication system.

Networked Intelligent Production available per customer's request.

ODM custom design available.

Specifications:

Garden Gas Hose Composite Braiding Machine

garden hose braiding machine,gas hose braiding machine.

| Type | carier per deck | carrier speed [RPM | braiding machine power | hauloff motor power | braiding pitch set up | carrier tension | braided hose OD | weight |

| BFB16W-114CFII | 16 | 80rpm(max) | 1.5KW*3 | 0.4KW | electronic parameter set | 0.4kg—5.0kg | ≤20mm | 850kg |

| BFB24W-114C | 24 | 40rpm(max) | 1.5KW | 0.4KW | electronic parameter set | 0.4kg—5.0kg | ≤24mm | 300kg |

| BFB24W-114CFS | 24 | 42rpm(max) | 2.2KW*2 | 0.4KW | electronic parameter set | 0.4kg—5.0kg | ≤24mm | 530kg |

| BFB24W-114D | 24 | 40rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 300kg | |

| BFB24W-114DS | 24 | 40rpm(max) | 1.5KW*2 | 0.4KW | electronic parameter set | 0.4kg—5.0kg | ≤24mm | 530kg |

| BFB32W-114D | 32 | 44rpm(max) | 2.0KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤32mm | 360kg | |

| BFB36W-114C | 36 | 29rpm(max) | 3.0KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤36mm | 400kg |

| BFB36W-114CI | 36 | 29rpm(max) | 3.0KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤36mm | 400kg |

| BFB36W-114D | 36 | 29rpm(max) | 3.0KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 400kg | |

| BFB48W-114C | 48 | 15rpm(max) | 5.5KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤48mm | 400kg |

| BFB48W-114CF | 48 | 15rpm(max) | 5.5KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤48mm | 580kg |

| BFB48W-114D | 48 | 20rpm(max) | 5.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤48mm | 580kg |

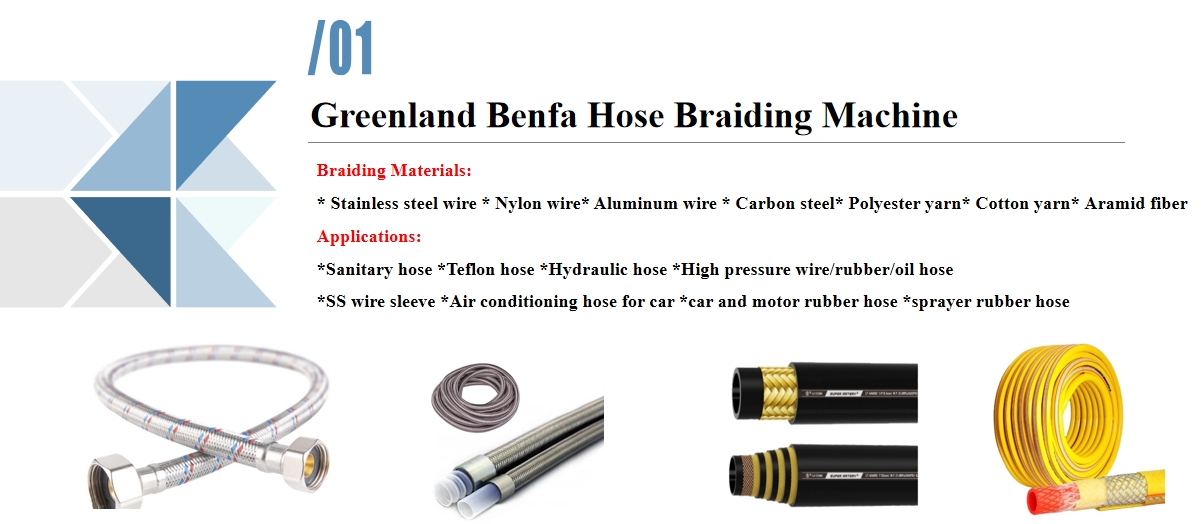

Applications:

Garden Gas Hose Composite Braiding Machine

Widely used in various industries such as: automobile brake tube, automobile air conditioner hose, wire & cable .etc ,

suitable for braiding stainless steel wire ,cotton yarn, glass fiber, aramid yarn, carbon fiber and other metallic wire and composite yarn.

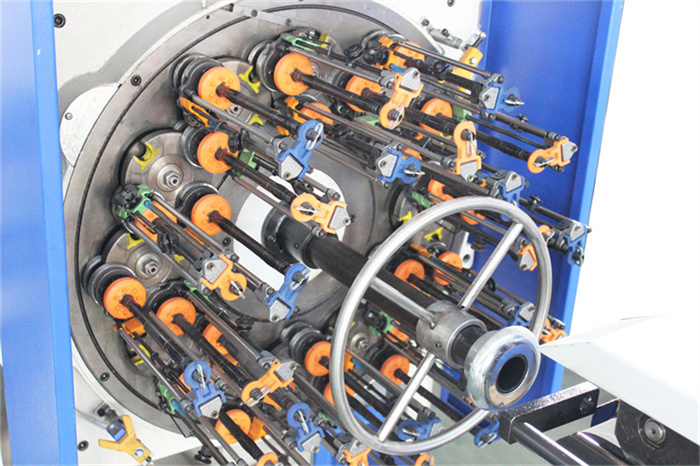

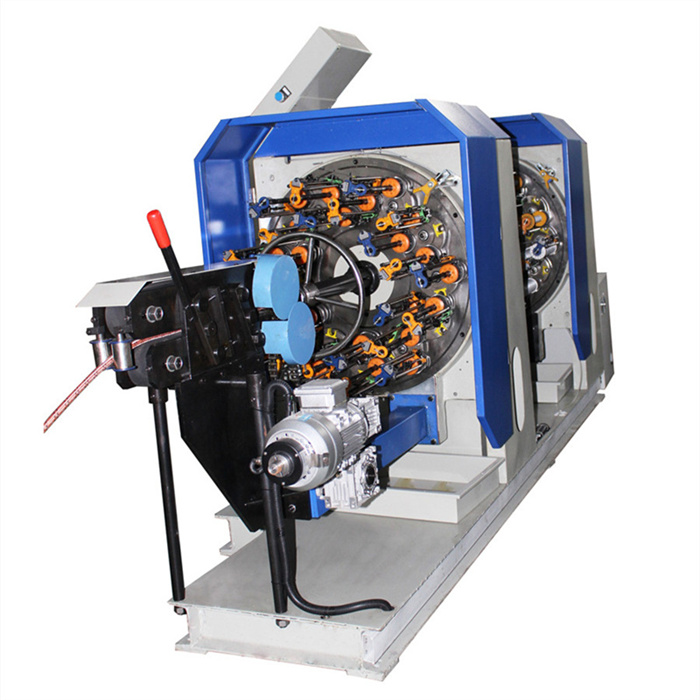

Product Detail:

Garden Gas Hose Composite Braiding Machine

garden hose braiding machine,gas hose braiding machine

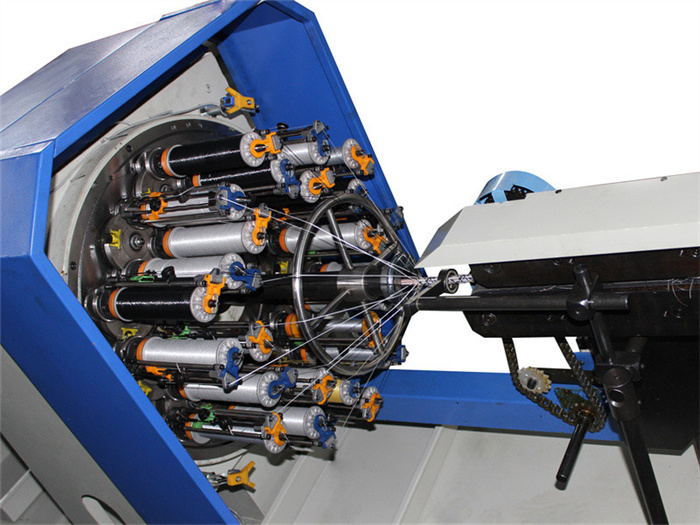

details as below photos:

Description:

Garden Gas Hose Composite Braiding Machine

garden hose braiding machine,gas hose braiding machine

114W:with horn gear OD 114mm,suitable for bobbin OD ≤ 58mm

carriers per deck | bobbin dimension |

8-96 | 56×22×170mm |

carrier speed [RPM] | bobbin capacity |

15-42 | 130 cm3-360 cm³ |

The BFB-114W series horizontal automatic braider, designed by Greenland Benfa Technology, emerges as a versatile and efficient

solution for various industries, specifically tailored for applications in the garden and gas hose manufacturing.

This braiding machine, equipped with a horn gear featuring an outer diameter of 114mm and suitable for bobbins with an outer

diameter of ≤ 58mm, combines advanced features to meet the demands of contemporary production processes.

Designed to handle hard and soft core braiding, as well as single and multiple-layer braiding, the BFB-114W series finds widespread

use in diverse industries. Applications span from automobile brake tubes to air conditioner hoses and wire & cable manufacturing.

Its adaptability extends to a range of braiding materials, including stainless steel wire, cotton yarn, glass fiber,

aramid yarn, carbon fiber, and other metallic wires and composite yarns.

One of the standout features of this braiding machine is its efficiency in operation. With one worker capable of overseeing several

machines simultaneously, the production process becomes streamlined. Moreover, the machine is equipped with an automated system

that stops and sounds alarms in response to issues such as broken wires, depleted wire supplies, or the absence of tubing or rubber sheets.

This not only enhances safety protocols but also contributes to uninterrupted production.

CNC control is another key attribute, allowing for easy adjustment of braid pitch (angle) and real-time monitoring of the machine's status.

The incorporation of features for data storage and safety protection adds to the overall efficiency and reliability of the machine.

Productivity is a crucial aspect of the BFB-114W series, and the formula for calculating it emphasizes the carrier pitch (RPM) and braid pitch (mm/min). The machine boasts a maximum carrier RPM of 50, showcasing its capability for high-speed and efficient braiding processes.

In terms of aesthetics and functionality, the braiding machine features a professional industry design with a patented outer look.

This not only contributes to a good outer appearance but also reflects Greenland Benfa's commitment to innovative design in the field.

Safety and environmental considerations are integral to the machine's design, with low noise levels tested at 78dB for the enclosed braider.

This ensures a safe and pleasant working environment for operators.

The automatic lubrication system, facilitated by Oil collecting circulating periodical automatic lubrication, minimizes oil stains and contributes

to a cleaner and more efficient production process.

For manufacturers looking for interconnected and intelligent production systems, the machine offers networked intelligent production options

per customer's request. This connectivity aligns with the growing trend of smart manufacturing.

The carriers per deck range from 8 to 96, providing flexibility to accommodate different production scales.

The bobbin dimensions of 56×22×170mm and 93×30x210mm, carrier speed ranging from 15 to 42 RPM, and a bobbin capacity of 130cm³ to 360cm³

contribute to the machine's adaptability and efficiency.

In conclusion, the BFB-114W series horizontal automatic braider from Greenland Benfa Technology serves as a technologically advanced and adaptable

solution for garden and gas hose braiding. With its versatile capabilities, user-friendly features, safety measures, CNC control, productivity enhancements,

and customization options, this braiding machine exemplifies the innovation and excellence that Greenland Benfa brings to the industry.