Double Deck Fine Wire Hose Braiding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: sanitary, cable, high-pressure hose industries,

Carrier Per Deck: 16,20,32,36,48

Braided Hose OD: 16,20,32,36,48mm

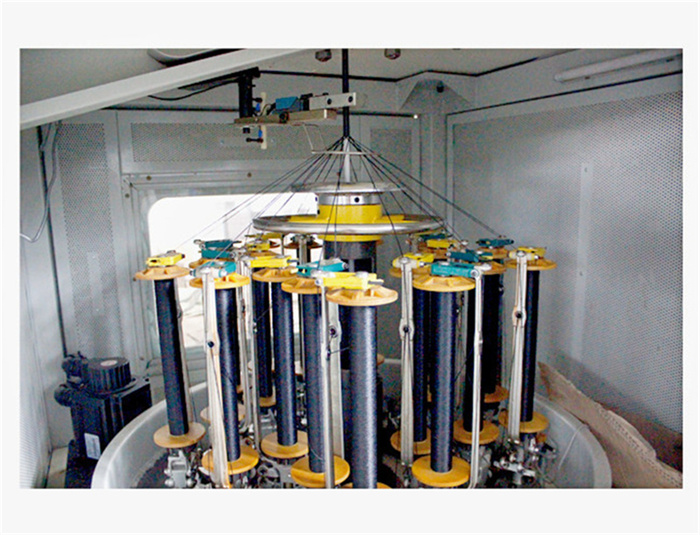

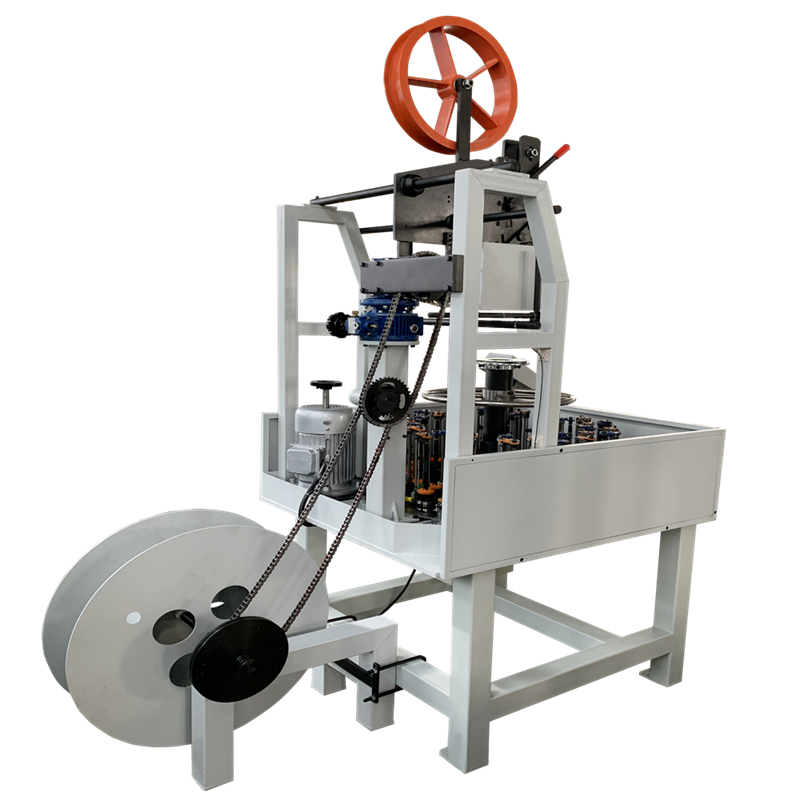

Greenland Benfa techology Double Deck Fine Wire Hose Braiding Machine

double deck hose braiding machine, Fine wire braiding machine,Hose Braiding Machine

1, High automatic

2, Adopt adjustable speed to accommodate pitch. don't need to change gear.

3, High efficiency production

4, Low noise

5, Easy maintenance

6, Customized

Download

Greenland Benfa techology Double Deck Fine Wire Hose Braiding Machine

double deck hose braiding machine, Fine wire braiding machine,Hose Braiding Machine

Fine wire braiding machine

double deck hose braiding machine

Main feature:

High automatic extent broken ,empty bobbin or no tube automatic machine self-closed.

Adopt adjustable speed to accommodate pitch. don't need to change gear.

High efficiency production three times than present usual machine per hour ,the max production reach to 98m/hour

Low noise ,transmission and pulling system adopt absorbing sound ,reducing shake and inserting equipment.

Easy maintenance ,transmission flexible structure easy install and remove

We can design the machine as customer request.

Specifications:

Greenland Benfa technology hose braiding machine 140 series Automatic Hose Braiding Machine has different specifications.

car and motor rubber hose braiding machine,car hose braiding machine,circular braiding machine

| Type | carrier per deck | carrier speed [RPM] | braiding machine power | haul off motor power | braiding pitch set up | carrier tension | braided hose OD | Weight |

| BFB16L-140CFS | 16 | 55rpm(max) | 1.5KW*2 | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤16mm | 300kg |

| BFB20L_140B | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L_140B II | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L-140BF | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L-140CF | 20 | 44rpm(max) | 1.5KW | 0.55Kw | electronic parameter set | 0.4kg-5.0kg | ≤20mm | 350kg |

| BFB24L-140CFS | 24 | 42rpm(max) | 1.5KW*2 | 0.55KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 580kg |

| BFB24L-140AF | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140AF II | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140B | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140B II | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140BF | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140CF | 24 | 42rpm(max) | 1.5KW | 0.55KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 380kg |

| BFB20L+24L-140CFS I | 24 | 37rpm(max) | 1.5KW*2 | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 700kg |

| BFB24L+24L-140CFS I | 24 | 37rpm(max) | 1.5KW*2 | 0.75Kw | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 700kg |

| BFB24L-140CS | 24 | 37rpm(max) | 1.5KW*2 | 0.55Kw | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 630kg |

| BFB24L-140D | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140DI | 24 | 37rpm(max) | 1.5xW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB32L-140A | 32 | 28rpm(max) | 2 2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤32mm | 430kg | |

| BFB32-140B | 32 | 28rpm(max) | 2 2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤32mm | 430kg | |

| BFB32L-140CF | 32 | 28rpm(max) | 2.2KW | 0.75KW | ectronic pararmeter set | 0.4kg-5.0kg | ≤32mm | 430kg |

| BFB36L-140AF | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140B | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140BF | 36 | 29rpm(max) | 2 2xw | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140CF | 36 | 29rpm(max) | 2.2KW | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤36mm | 520kg |

| BFB36L-140D | 36 | 29rpm(max) | 3.0KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB48L-140B | 48 | 25rpm(max) | 3.0KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤48mm | 550kg | |

| BFB48L-140CF | 48 | 25rpm(max) | 3.0Kw | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤48mm | 550kg |

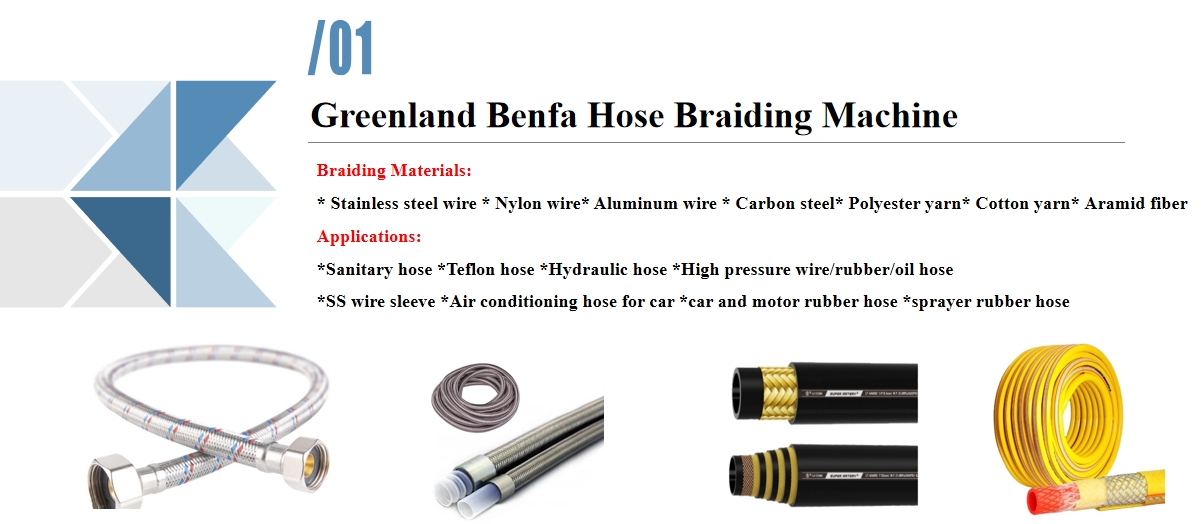

Applications:

Greenland Benfa hose braiding machine widely use in different industries,such as sanitary hose , high pressure wire/rubber/oil hose, Teflon hose,

SS wire sleeve, air conditioning hose , car and motor rubber hose, sprayer rubber hose and so on.

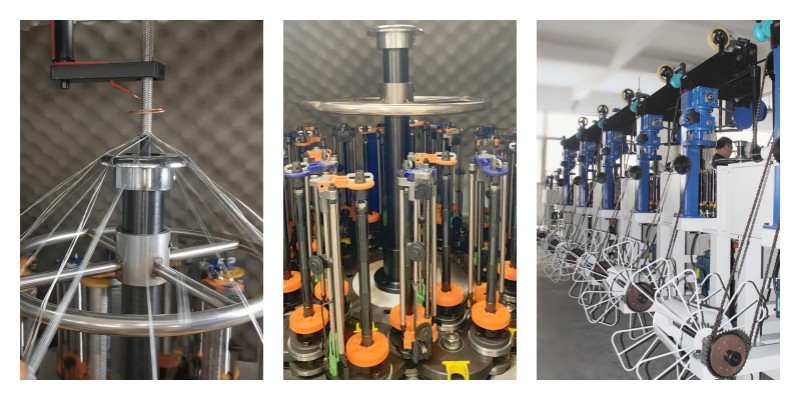

Product Detail:

Greenland Benfa technology hose braiding machine details as below photos:

Description:

Greenland Benfa technology hose braiding machine140L:with horn gear OD140mm,suitable for bobbin OD ≤ 82mm

Double Deck Fine Wire Hose Braiding Machine

double deck hose braiding machine, Fine wire braiding machine,Hose Braiding Machine

carriers per deck | bobbin dimension |

8-96 | 80×28×277mm |

carrier speed [RPM] | bobbin capacity |

20-55 | 130 cm3-360 cm3 |

Double Deck Fine Wire Hose Braiding Machine:

Greenland Benfa introduces a paradigm shift in hose braiding technology with the Double Deck Fine Wire Hose Braiding Machine.

Engineered for efficiency, this machine minimizes labor costs as a single worker can operate up to 10 machines simultaneously.

It belongs to the category of double deck hose braiding machines, fine wire braiding machines, and general hose braiding machines, offering versatility and enhanced productivity.

Main Features:

1. High Automation:The double deck hose braiding machine boasts a high level of automation with an automatic extent for handling broken wires, empty bobbins, or situations with no tubing. This self-closed system enhances operational efficiency.

2. Adjustable Speed: Adaptability is a core feature, with adjustable speed accommodating different pitches without the need for gear changes. This innovative feature simplifies the operational process and enhances overall flexibility.

3. Efficient Production:The Double Deck Fine Wire Hose Braiding Machine achieves remarkable efficiency, producing three times more than .present usual machines per hour. The maximum production speed reaches an impressive 98 meters per hour, ensuring a significant boost in manufacturing output.

4. Low Noise Operation: Noise reduction is a key focus, with the transmission and pulling systems adopting sound-absorbing features.This minimizes noise levels, reduces shake during operation, and enhances the overall workplace environment.

5. Easy Maintenance:The machine's transmission system features a flexible structure, facilitating easy installation and removal.

In summary, the Greenland Benfa Double Layer Fine Wire Hose Braider offers efficiency, adaptability and customization options. We are known for providing complete hose braiding solutions covering hose winding machines, hose braiding machines, hose cutting machines, hose assembly machines and hose crimping machines. Also offers unbeatable ex-factory prices and comprehensive hose braiding machine OEM/ODM services, including installation, maintenance and spare parts supply.