Belt Braided Rope And Cord Making Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

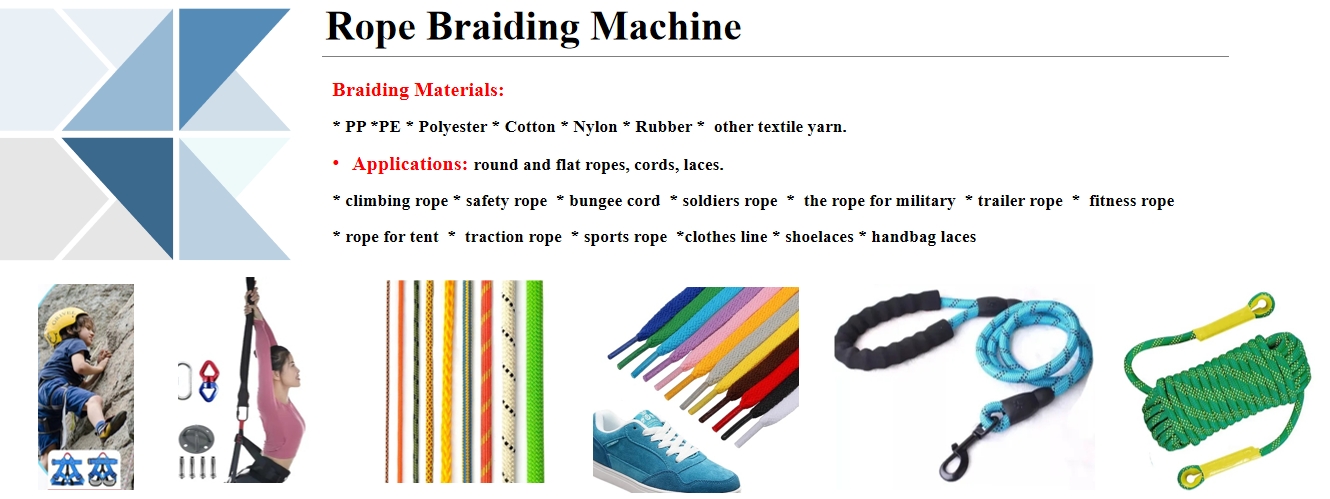

Application: * climbing rope * safety rope * bungee cord * soldiers rope * the rope for military * trailer rope * fitness rope * rope for tent * traction rope * sports rope *clothes line * shoelaces * handbag laces

Carrier Per Deck: 3-120

Belt Braided Rope And Cord Making Machine

1)user-friendly operation and maintenance.

2)utilization of top-class parts for long service life,

3)low horsepower and electricity costs,

4)automatic stop in case of yarn issues,

5)oil-free braiding suitable for transparent materials,

Download

Belt Braided Rope And Cord Making Machine

belt braiding machine,braided rope making machine,cord braiding machine

belt braiding machine

cord braiding machine

Main feature:

1) pace-saving compact design.

2) user-friendly operation and maintenance.

3) utilization of top-class parts for long service life,

4) low horsepower and electricity costs,

5) automatic stop in case of yarn issues,

6) oil-free braiding suitable for transparent materials,

7) adjustable cord density,

8) no continuous operator attendance required,

9) versatility for hybrid braiding wire and chemical fiber applications.

10) fully covered design reducing noise by 80%.

These attributes collectively make it an efficient, adaptable, and convenient solution for various braiding needs in different industrial settings.

Specifications:

Belt Braided Rope And Cord Making Machine

belt braiding machine,braided rope making machine,cord braiding machine

| Spindle | Head number | Pitch size(mm) | Braiding type | Bobbin size(mm) | Braiding range(mm) | Speed ( RPM ) |

| 3 | 16 | 80 | flat | Φ43*112/140 | 1-6 | 360 |

| 5 | 4 | 80 | flat | Φ43*112/140 | 2-5 | 360 |

| 9 | 4 | 80 | flat | Φ43*112/140 | 3-6 | 360 |

| 12 | 4 | 80 | round | Φ43*112/140 | Φ1-6 | 360 |

| 13 | 4 | 80 | flat | Φ43*112/140 | 3-7 | 360 |

| 16 | 2 | 80 | round | Φ43*112/140 | Φ1-8 | 360 |

| 16 | 4 | 80 | round | Φ43*112/140 | Φ1-8 | 360 |

| 17 | 4 | 80 | flat | Φ43*112/140 | 4-8 | 360 |

| 20 | 4 | 80 | round | Φ43*112/140 | Φ3-10 | 360 |

| 21 | 4 | 80 | flat | Φ43*112/140 | 12-15 | 360 |

| 24 | 2 | 80 | round | Φ43*112/140 | Φ3-12 | 360 |

| 25 | 2 | 80 | flat | Φ43*112/140 | 15-18 | 360 |

| 32 | 2 | 80 | round | Φ43*112/140 | Φ6-15 | 360 |

| 33 | 2 | 80 | flat | Φ43*112/140 | 18-25 | 360 |

| 40 | 1 | 80 | round | Φ43*112/140 | Φ8-16 | 360 |

| 40 | 2 | 80 | round | Φ43*112/140 | Φ8-16 | 360 |

| 48 | 1 | 80 | round | Φ43*112/140 | Φ8-20 | 360 |

| 56 | 1 | 80 | round | Φ43*112/140 | Φ8-22 | 360 |

| 64 | 1 | 80 | round | Φ43*112/140 | Φ8-24 | 360 |

| 120 | 1 | 80 | round | Φ43*112/140 | Φ15-36 | 360 |

Applications:

Belt Braided Rope And Cord Making Machine

belt braiding machine,braided rope making machine,cord braiding machine

Applications:

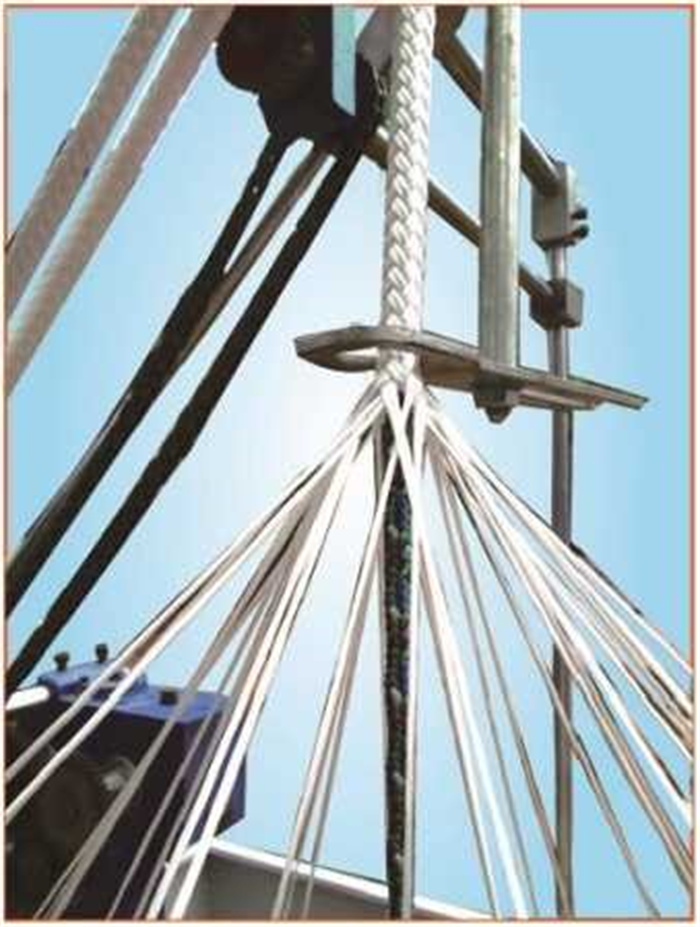

This model braiding machines Suitable for the braiding of :

climbing cord, safety rope, bungee cord, solider cord , the rope for military , trailer rope, fitness rope, rope or tent, traction rope, sport rope, fire rope, bungee cord. mountaineering ropes

shoelace, drawing string, hollow cord, elastic cord, and decorative ribbons and elastic bands, clothes ropes, security lines and pet neck line, Sports &Leisure accessory , fish thread.

Braiding material:

Cotton, PP, PE,Fiber glass, nylon, Carbon Fiber,PET and other composite materials.

Description:

Belt Braided Rope And Cord Making Machine

belt braiding machine,braided rope making machine,cord braiding machine

The rope braiding machine, with its versatile applications and advanced features, stands as a reliable solution for diverse industrial needs.

Specifically designed for the braiding of climbing cords, safety ropes, bungee cords, soldier cords, military ropes, trailer ropes, fitness ropes,

tent ropes, traction ropes, sport ropes, fire ropes, and mountaineering ropes, it caters to a wide range of uses.

2. This model accommodates various braiding materials, including cotton, PP, PE, fiber glass, nylon, carbon fiber, PET, and other composite materials.

Its adaptability to different materials enhances its functionality and makes it a go-to choice for manufacturers dealing with a variety of products.

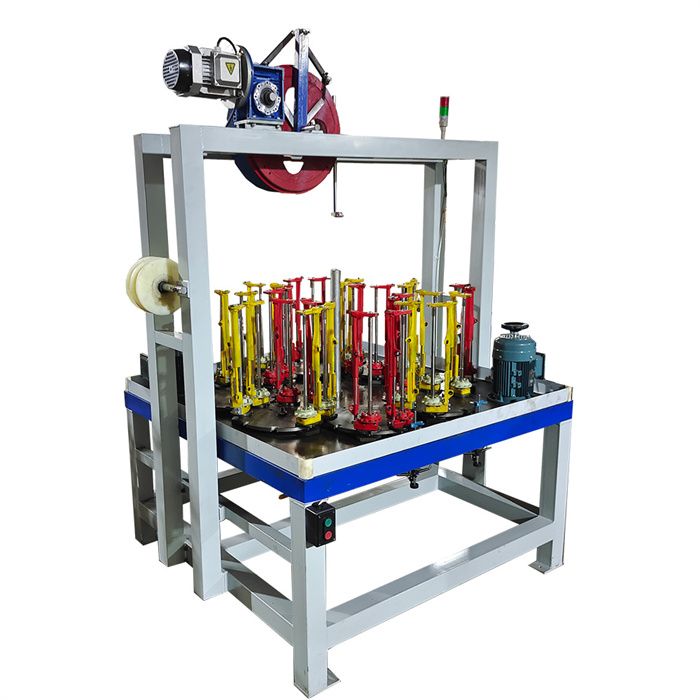

3. The main features of this rope braiding machine underscore its efficiency and user-friendly design. The space-saving compact design ensures

optimal use of available space in industrial settings. User-friendly operation and maintenance make it accessible to operators with varying levels

of expertise, contributing to a seamless production process.

4. Utilizing top-class parts is a testament to the machine's commitment to durability and long service life. This, combined with low horsepower and

electricity costs, makes it an economically viable option for businesses aiming to optimize their operational expenses.

5. The automatic stop feature in case of yarn issues adds an extra layer of safety and prevents potential damage, ensuring a smooth and uninterrupted

production flow. The machine's oil-free braiding capability is particularly advantageous when working with transparent materials,

maintaining product quality and visual appeal.

6. The adjustable cord density feature adds a layer of customization, allowing manufacturers to tailor the output according to specific requirements.

Importantly, the machine eliminates the need for continuous operator attendance, freeing up manpower and increasing overall operational efficiency.

7. The versatility of this rope braiding machine extends to its application in hybrid braiding wire and chemical fiber scenarios, broadening its use across

different industries. Additionally, the option for a fully covered design, reducing noise by 80%, addresses environmental considerations and provides

a more comfortable working environment.

In conclusion, the rope braiding machine's comprehensive features, including its applications, material compatibility, and user-friendly design,

position it as an efficient, adaptable, and convenient solution for various braiding needs in different industrial settings. Its capabilities make it a valuable

asset for manufacturers seeking precision, reliability, and flexibility in their production processes.