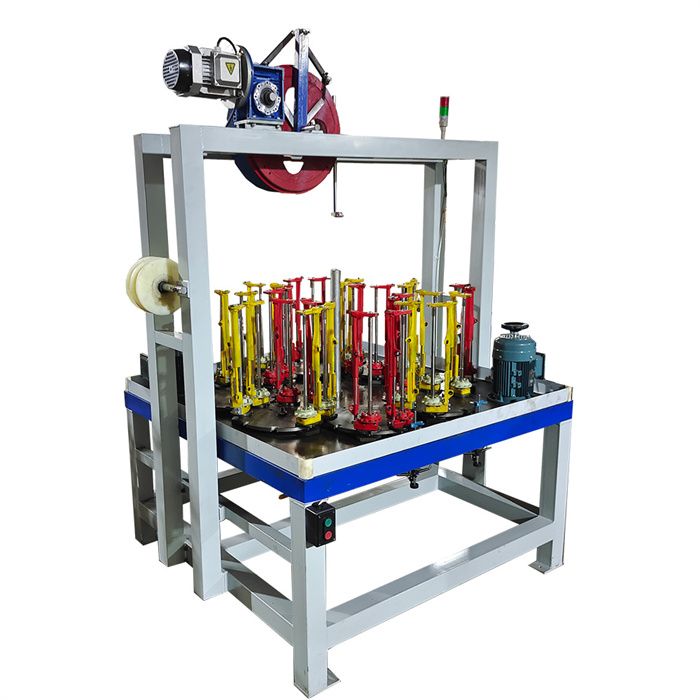

Automatic 16 24 48 Carrier Rope Cord Braiding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: * climbing rope * safety rope * bungee cord * soldiers rope * the rope for military * trailer rope * fitness rope * rope for tent * traction rope * sports rope *clothes line * shoelaces * handbag laces

Carrier Per Deck: 3-120

Automatic 16 24 48 Carrier Rope Cord Braiding Machine

1) Ease of operation and maintenance simplifies the user experience.

2) While top-class parts contribute to an extended service life.

3) This machine operates with low horsepower and electricity costs.

4) Enhanced performance is achieved through the integration of a transducer.

5) Automatic stop unit for wire breaking, and a rolling-back unit.

6) The absence of oil spraying makes it particularly suitable for transparent materials.

Download

Belt Braided Rope And Cord Making Machine

Product Description:

Introducing our Automatic 16, 24, 48 Carrier Rope Cord Braiding Machine, a state-of-the-art solution for high-speed and precise braiding operations.

Engineered for versatility and efficiency, this machine is designed to meet the demands of various industries requiring intricate and durable braided products.

Product Features:

Carrier Options:

Our braiding machine offers flexibility with selectable carrier configurations, including 16, 24, and 48 carriers.

This allows manufacturers to tailor the machine to their specific production needs, accommodating a variety of braiding patterns and thicknesses.

Advanced Braiding Mechanism:

The machine is equipped with an advanced braiding mechanism featuring precision-engineered discs.

This mechanism ensures uniform and tightly woven braids, meeting the highest standards of quality in the industry.

Spool and Bobbin System:

The machine incorporates an efficient spool and bobbin system, effectively managing material strands with precision.

This system ensures even tension distribution, contributing to consistent braiding quality.

Adjustable Tension Control:

An integrated tensioning system allows for precise control over the tension applied to different carriers, ensuring optimal braiding results

and adaptability to various material properties.

Variable Speed Control:

The machine features a variable speed control system, providing operators with the flexibility to adjust braiding speed based on specific production requirements.

This feature enhances overall efficiency and productivity.

Robust Frame Construction:

Constructed with a durable and stable frame, the machine provides a sturdy foundation for continuous and reliable operation.

The robust design ensures longevity and minimizes maintenance needs.

User-Friendly Interface:

Featuring an intuitive control panel, the machine is easy to operate. Operators can effortlessly set parameters, monitor the braiding process,

and make adjustments as needed.

Automated Operation:

Designed for automation, our braiding machine minimizes manual intervention, streamlining the production process and increasing overall efficiency.

Safety Features:

Equipped with safety features, including emergency stop buttons and guards around moving parts, ensuring a secure working environment for operators.

Application Diversity:

Ideal for a wide array of applications, including the production of ropes, cords, and braided products used in industries such as marine, construction, and textiles.

Energy-Efficient Operation:

Our braiding machine is designed with energy efficiency in mind, contributing to cost savings and environmental sustainability.

Compliance with Standards:

The machine complies with industry standards, ensuring that the braided products meet quality and safety requirements.

6 24 48 carrier braiding machine

automatic rope braiding machine

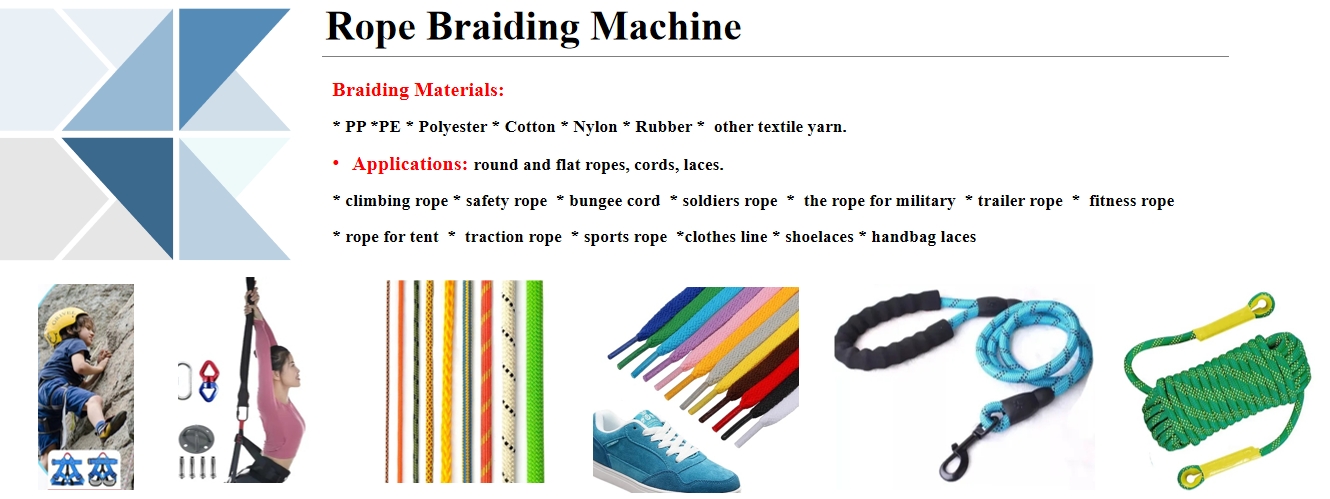

Rope Braiding Machine

Main feature:

1) reasonable structure requires minimal space, ensuring efficient use of work areas.

2) Ease of operation and maintenance simplifies the user experience.

3) while top-class parts contribute to an extended service life.

4) This machine operates with low horsepower and electricity costs.

5) Enhanced performance is achieved through the integration of a transducer.

6) automatic stop unit for wire breaking, and a rolling-back unit.

7) The absence of oil spraying makes it particularly suitable for transparent materials.

8) Preserving their integrity and appearance.

9) The machine boasts a larger bobbin volume and easier tenability adjustment, enhancing its versatility.

10) The vast application area, including the capability for hybrid braiding wire and chemical fiber, underscores its adaptability across diverse industries.

11) A notable feature is the option for a fully enclosed safety hood, reducing noise levels by 10-15 db.

This not only addresses environmental considerations but also creates a more comfortable and safer working environment for operators.

In summary, the rope braiding machine combines a reasonable structure, user-friendly operation, and top-quality components to offer a reliable and efficient

solution for various braiding needs. Its versatility, durability, and noise reduction features position it as a valuable asset in different industrial settings,

ensuring optimal performance and cost-effectiveness.

Specifications:

Belt Braided Rope And Cord Making Machine

belt braiding machine,braided rope making machine,cord braiding machine

| Spindle | Head number | Pitch size(mm) | Braiding type | Bobbin size(mm) | Braiding range(mm) | Speed ( RPM ) |

| 3 | 16 | 80 | flat | Φ43*112/140 | 1-6 | 360 |

| 5 | 4 | 80 | flat | Φ43*112/140 | 2-5 | 360 |

| 9 | 4 | 80 | flat | Φ43*112/140 | 3-6 | 360 |

| 12 | 4 | 80 | round | Φ43*112/140 | Φ1-6 | 360 |

| 13 | 4 | 80 | flat | Φ43*112/140 | 3-7 | 360 |

| 16 | 2 | 80 | round | Φ43*112/140 | Φ1-8 | 360 |

| 16 | 4 | 80 | round | Φ43*112/140 | Φ1-8 | 360 |

| 17 | 4 | 80 | flat | Φ43*112/140 | 4-8 | 360 |

| 20 | 4 | 80 | round | Φ43*112/140 | Φ3-10 | 360 |

| 21 | 4 | 80 | flat | Φ43*112/140 | 12-15 | 360 |

| 24 | 2 | 80 | round | Φ43*112/140 | Φ3-12 | 360 |

| 25 | 2 | 80 | flat | Φ43*112/140 | 15-18 | 360 |

| 32 | 2 | 80 | round | Φ43*112/140 | Φ6-15 | 360 |

| 33 | 2 | 80 | flat | Φ43*112/140 | 18-25 | 360 |

| 40 | 1 | 80 | round | Φ43*112/140 | Φ8-16 | 360 |

| 40 | 2 | 80 | round | Φ43*112/140 | Φ8-16 | 360 |

| 48 | 1 | 80 | round | Φ43*112/140 | Φ8-20 | 360 |

| 56 | 1 | 80 | round | Φ43*112/140 | Φ8-22 | 360 |

| 64 | 1 | 80 | round | Φ43*112/140 | Φ8-24 | 360 |

| 120 | 1 | 80 | round | Φ43*112/140 | Φ15-36 | 360 |

Belt Braided Rope And Cord Making Machine

belt braiding machine,braided rope making machine,cord braiding machine

Applications:

This model braiding machines Suitable for the braiding of :

climbing cord, safety rope, bungee cord, solider cord , the rope for military , trailer rope, fitness rope, rope or tent, traction rope, sport rope, fire rope, bungee cord. mountaineering ropes

shoelace, drawing string, hollow cord, elastic cord, and decorative ribbons and elastic bands, clothes ropes, security lines and pet neck line, Sports &Leisure accessory , fish thread.

Braiding material:

Cotton, PP, PE,Fiber glass, nylon, Carbon Fiber,PET and other composite materials.

Upgrade your production capabilities with our Automatic 16, 24, 48 Carrier Rope Cord Braiding Machine. Offering precision, efficiency, and versatility,

this machine is the perfect choice for manufacturers seeking to meet the diverse demands of the braiding industry with excellence.

Please do not hesitate to contact us, We can provide detailed information based on your specific requirements and applications.