24 Carrier Braider 4 Strand Braiding Machine Diy

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: sanitary, cable, high-pressure hose industries,

Carrier Per Deck: 16,24,32

Braided Hose OD: 16,24,32

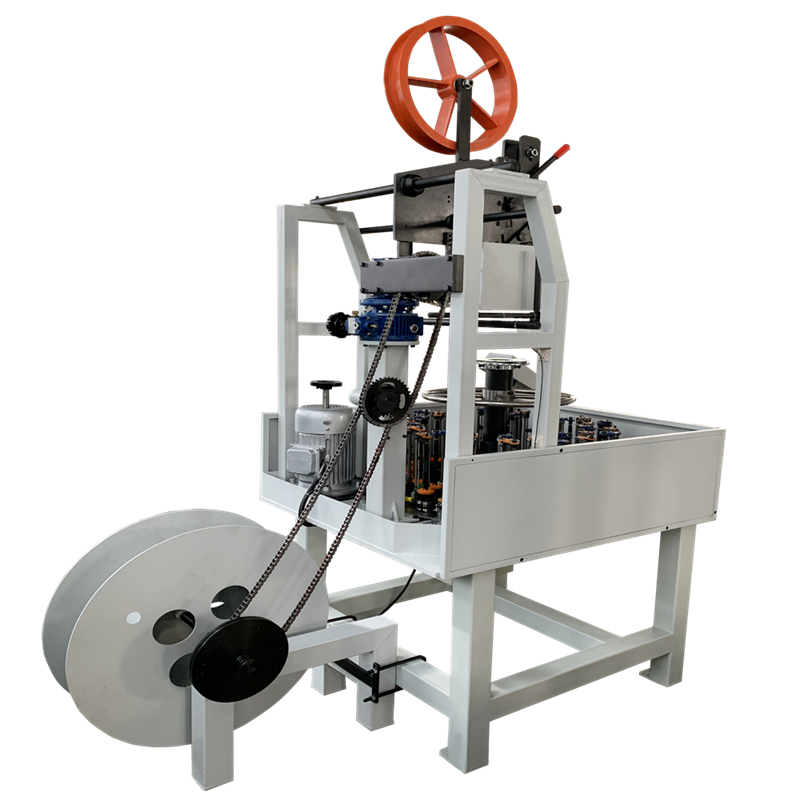

Greenland Benfa hose braiding machine

24 Carrier Braider, 4 Strand Braiding Machine Diy,3d hose braiding machine

1, Hot sale style

2, Automatic

3,High effecitve

4,Fast speed.

5,Easy operation.

6,Less labor, one worker can operate 10 machines

Download

24 Carrier Braider 4 Strand Braiding Machine Diy

Greenland Benfa hose braiding machine

Main feature:

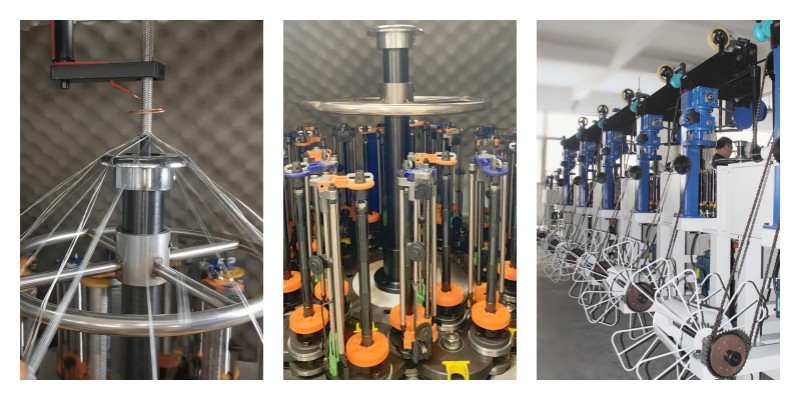

Greenland Benfa hose braiding machine Oil bath lubrication system are used, stable carrier tension, easy to maintain.

Patented in house designed plate with guide, prolong machine life.

Low noise , tested noises 78dB for enclosed braider, noise and shocking absorbing design.

Carrier rpm is 5% higher than the horizontal model carrier rpm can reach up to 310rpm , high productivity.

Greenland Benfa hose braider stops & alarms when broken wire, out of wire, out of tubing or rubber sheet detected, ensure machine runs safely.

Custom design available per request.

Specifications:

Greenland Benfa hose braiding machine 114 series Automatic Hose Braiding Machine has different specifications to meet your different demand,

for example 24 Carrier Braider, 4 Strand Braiding Machine,Braiding MachineDiy

Type | carrier per deck | carrier speed RPM | braiding machine power | haul off motor power | braiding pitch set up | carrier tension | braided hose OD | weight |

| BFB16L-1148 | 16 | 55rpm(max) | 0.75KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤16mm | 280kg | |

| BFB24L-114AF | 24 | 45rpm(max) | 1.1KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 305kg | |

| BFB24L-114B | 24 | 45rpm(max) | 1.1KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 305kg | |

| BFB24L-114B1 | 24 | 45rpm(max) | 1.1KW | mechanical variable speed drive | 0.4kg-5.Okg | ≤24mm | 305kg | |

| BFB24L-114B Ⅱ | 24 | 45rpm(max) | 1.1KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 305kg | |

| BFB24L-114BF | 24 | 45rpm(max) | 1.1KW | mechanical variable speed drive | 0.4kg-5.Okg | ≤24mm | 305kg | |

| BFB24L-114BS | 24 | 45rpm(max) | 1.5KW-2 | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 600kg | |

| BFB24L-114C | 24 | 45rpm(max) | 1.1KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤24mm | 305kg |

| BFB24L-114CF | 24 | 45rpm(max) | 1.1KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤24mm | 305kg |

| BFB24L-114D | 24 | 52rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 330kg | |

| BFB24L-114Dl | 24 | 40rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤24mm | 330kg | |

| BFB32L-114B | 32 | 35rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤32mm | 400kg | |

| BFB36L-114B | 36 | 29rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 450kg | |

| BFB36L-114BI | 36 | 29rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 450kg | |

| BFB36L-114BⅡI | 36 | 29rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 450kg | |

| BFB36L-114C | 36 | 29rpm(max) | 1.5KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤36mm | 450kg |

| BFB36L-114CF | 36 | 29rpm(max) | 1.5KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤36mm | 450kg |

| BFB36L-114D | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 475kg | |

| BFB36L-114DI | 36 | 29rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 475kg | |

| BFB36L-114DⅡ | 36 | 29rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤36mm | 475kg | |

| BFB48L-114AF | 48 | 20rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤48mm | 128Okg | |

| BFB48L-114B | 48 | 20rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg—5.0kg | ≤48mm | 1280kg | |

| BFB48L-114CF | 48 | 20rpm(max) | 2.2KW | 0.55KW | electronic parameter set | 0.4kg—5.0kg | ≤48mm | 1280kg |

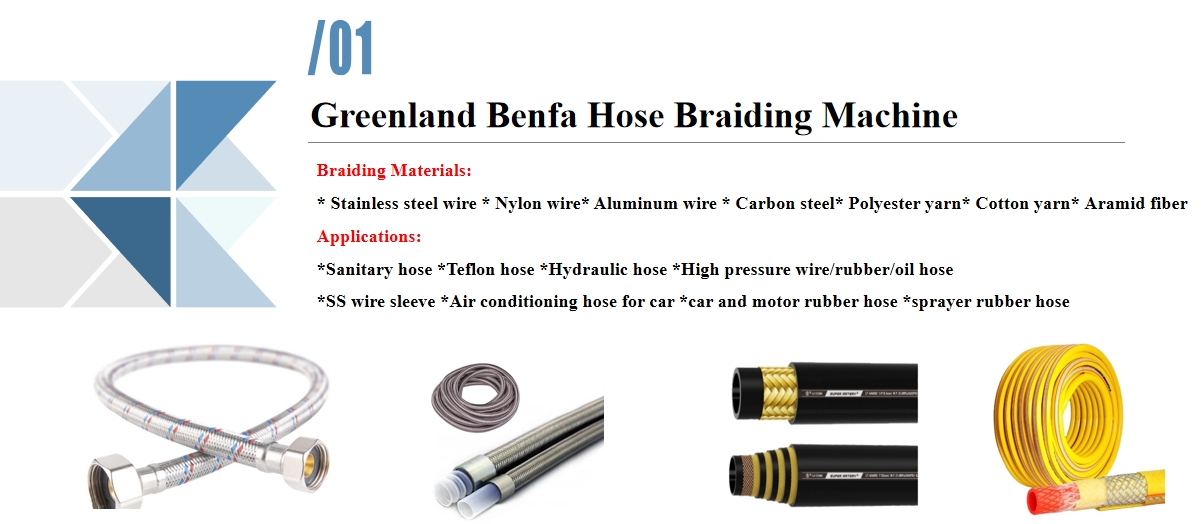

Applications:

Greenland Benfa hose braiding machine

Its versatile application spans across the sanitary, cable, and high-pressure hose industries, accommodating materials like

stainless steel wire, cotton yarn, aramid fiber, carbon fiber, and more.

Product Detail:

Greenland Benfa hose braiding machine details as below photos:

Description:

Greenland Benfa hose braiding machine114L series:with horn gear OD114mm,suitable for bobbin OD ≤ 58mm

3d hose braiding machine , 4 strand braiding machine,24 Carrier Braider,Braiding Machine Diy

carriers per deck | bobbin dimension |

8-96 | 56×22×170mm |

carrier speed [RPM] | bobbin capacity |

20-55 | 130 cm3-360 cm3 |

Greenland Benfa's cutting-edge hose braiding machines encompass a range of models, including the innovative 3D hose braiding machine, the versatile 4-strand braiding machine, and the high-capacity 24 Carrier Braider. With applications spanning from sanitary hoses to high-pressure wire/rubber/oil hoses, Teflon hoses, SS wire sleeves, air conditioning hoses, car and motor rubber hoses, to sprayer rubber hoses, these machines are designed to meet the diverse needs of modern manufacturing.

One of the standout features is the high level of automation across the 3D hose braiding machine, 4-strand braiding machine, and 24 Carrier Braider. This ensures not only efficiency in production but also a user-friendly experience. The oil bath lubrication system contributes to stable carrier tension, facilitating easy maintenance and enhancing the overall reliability of the machines.

Greenland Benfa takes pride in its patented in-house designed plate with a guide, a key component that significantly prolongs the life of the hose braiding machine. This commitment to durability is complemented by a low-noise operation, with tested noises as low as 78dB for enclosed braiders. The noise and shock-absorbing design further underscores the focus on creating a comfortable and safe working environment.

The carrier RPM, a critical factor influencing productivity, is impressively 5% higher than the horizontal model. With carrier RPM reaching up to 310rpm, these machines demonstrate exceptional productivity, making them well-suited for demanding manufacturing environments.

Safety is paramount, and Greenland Benfa's hose braiders are equipped with advanced features to ensure a secure operational environment. Stops and alarms activate when issues like broken wires, wire depletion, or the absence of tubing or rubber sheets are detected. This proactive approach safeguards the machine, preventing potential damage and ensuring the safety of the production process.

Moreover, Greenland Benfa accommodates customization requests, allowing manufacturers to tailor these hose braiding machines according to specific requirements. This flexibility underscores the adaptability of these machines to various production scenarios.

In conclusion, Greenland Benfa's 3D hose braiding machine, 4-strand braiding machine, and 24 Carrier Braider are at the forefront of technological innovation in hose braiding. With their emphasis on automation, efficiency, maintenance ease, low noise, and safety features, these machines cater to the evolving demands of modern manufacturing. Whether used in the production of sanitary hoses, high-pressure wire/rubber/oil hoses, or other applications, Greenland Benfa's hose braiding machines represent a reliable and advanced solution for the industry.