-

12-22 2023

Applications of Braiding Machines

Greenland Benfa Braiding machines are specialized textile equipment used for producing braided products, for example cords, ropes, laces, and hoses, by interlacing yarns or strands in a specific pattern. These machines come in various types, each with distinct applications and capabilities. Here is a detailed classification of braiding machines and their applications:

-

12-22 2023

What Products Can The Braiding Machine Produce?

Ropes, shoelaces, cords, and various types of trimmings. These machines play a crucial role in textile manufacturing by creating strong and intricate braided structures used in diverse applications like apparel, accessories, and industrial materials.

-

12-14 2023

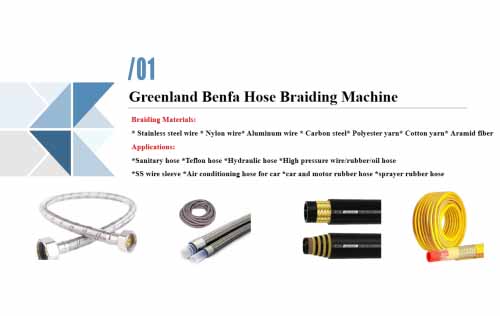

Applications of hose braiding machines

Greenland benfa hose braiding machines have a wide range of applications in different industries. These machines are capable of producing high-quality hoses that are used in various industrial and commercial applications. Below are some common applications of hose braiding machines.

-

12-12 2023

Types Of Hose Braiding Machines

Greenland Benfa 's hose braiding machines offer a tailored solution for various manufacturing requirements. The choice depends on factors like production volume, hose diameter, and material type. Whether opting for vertical, horizontal, 90-degree, automatic, manual, or plastic hose braiding machines, Benfa ensures a diverse range to meet the specific demands of your manufacturing operation.

-

12-08 2023

The Essential Parts For Hose Braiding Machine

Hose braiding machines rely on essential components to ensure optimal performance and longevity. The bobbin, a crucial part, holds the yarn or wire for braiding and can be crafted from materials like plastic, metal, or ceramic. The spindle, where the bobbin rotates, creates the braided pattern, while the tensioner maintains consistent yarn or wire feed at the correct tension for uniform braiding.

-

12-05 2023

How Is Braided Finishing Line Made?

braided fishing lines offer a range of benefits, from strength and durability to versatility in various fishing conditions. However, anglers must be mindful of their visibility, resistance to abrasion, and the challenges associated with knot tying and cutting. When chosen and handled with care, braided lines can be valuable assets in an angler's toolkit.