Revolutionizing Hose Assembly: The New Era of Smart Crimping Technology

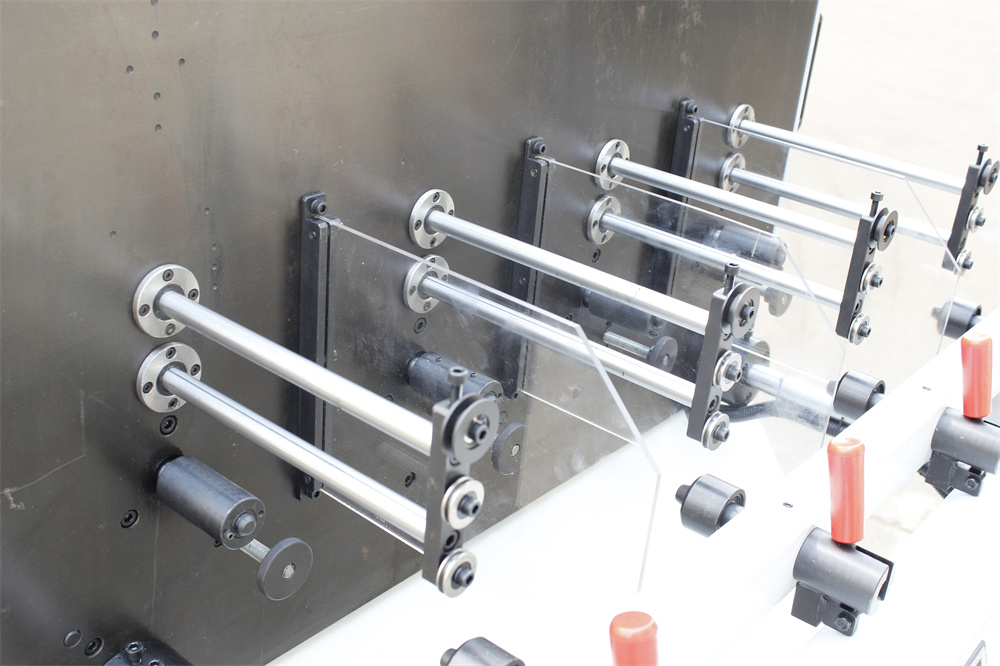

hydraulic hose machine

Innovative developments in hose assembly are being propelled forward by the introduction of advanced IoT-enabled crimping machines. These sophisticated crimpers go beyond mere fault detection; they offer comprehensive troubleshooting and problem-solving strategies. With enhanced capabilities, such as checking for sensor obstructions and executing simple maintenance calibrations, these machines empower users to handle potential issues with unprecedented efficiency.

The intelligent software of these IoT crimpers is a game-changer, significantly reducing machine downtime and elevating productivity to new heights. This leap in technology has transformed the operator experience, simplifying the training process and allowing for more intuitive machine handling.

The advancements extend to customer support, with remote troubleshooting now a robust feature. Service teams can connect to the crimper software remotely, bypassing the need for on-site visits, which saves time and costs. In tandem, mobile device management systems provide rapid and precise diagnostics, facilitating a swift response from support teams.

By streamlining the connection between the crimper and support services, these innovations ensure minimal downtime for the machinery. The crimping process has thus become more reliable than ever, maximizing operational efficiency and minimizing any risk of lost sales, all without compromising the machines' functionality or the safety of operations.