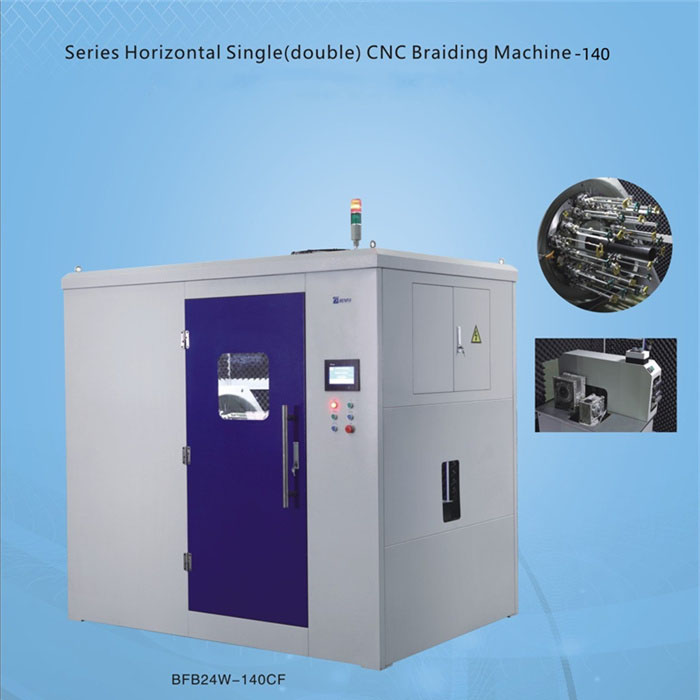

Sprayer Rubber Ptfe Teflon Hose Braiding Machine

Brand: Benfa

Country of origin: China

Technical Support: Longlife

Application: steel wire braided high pressure rubber tube ,steel wire braided sleeve , braided corrugated tube , high strength wire braided tube. Big diameter cable brake hose ,air conditioner hose

Carrier Per Deck: 16,20,24,28,32,36,48,64

Braided Hose OD: 16,20,24,28,32,36,55,140mm

Greenland Benfa techology Sprayer Rubber Ptfe Teflon Hose Braiding Machine

1, Machine stops & alarms when broken wire.

2, CNC controlled.

3, Suitable for rigid tube and big diameter tube.Big diameter cable brake hose ,air conditioner hose

4, Fast braiding speed

Greenland Benfa techology Sprayer Rubber Ptfe Teflon Hose Braiding Machine

Product Description:

The Sprayer Rubber PTFE Teflon Hose Braiding Machine is a specialized piece of equipment tailored for the precise manufacturing of hoses commonly used in sprayer applications. This machine is designed to produce hoses that integrate a rubber core with PTFE (Polytetrafluoroethylene) or Teflon lining for enhanced chemical resistance and flexibility. The braiding process further reinforces the hoses, making them well-suited for demanding spraying applications.

Product features:

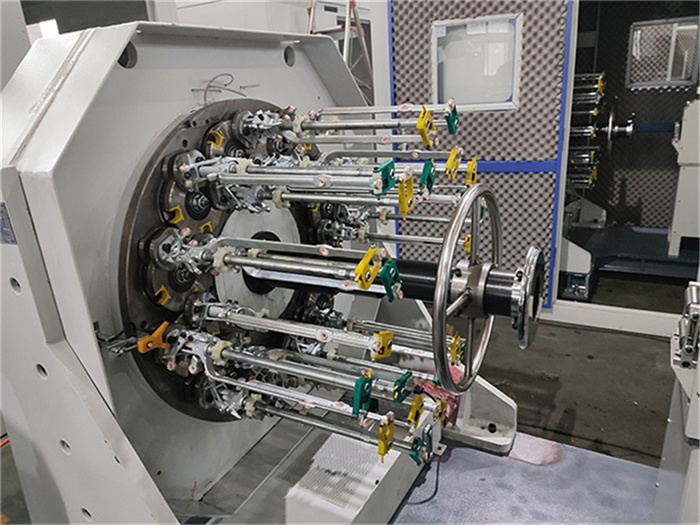

Sprayer Hose Braiding:

Engineered specifically for the braiding of hoses intended for sprayer applications. The machine ensures accurate and uniform braiding around the rubber core.

Rubber and PTFE Integration:

Capable of handling both rubber and PTFE materials, providing the desired combination of flexibility and chemical resistance for sprayer hoses.

Braiding Materials:

Designed to work with various braiding materials, including stainless steel or other suitable alloys, to reinforce the hoses and enhance their strength.

Adjustability:

Adjustable settings to accommodate different hose diameters, lengths, and braiding patterns. This adaptability is crucial for meeting diverse production requirements in the sprayer industry.

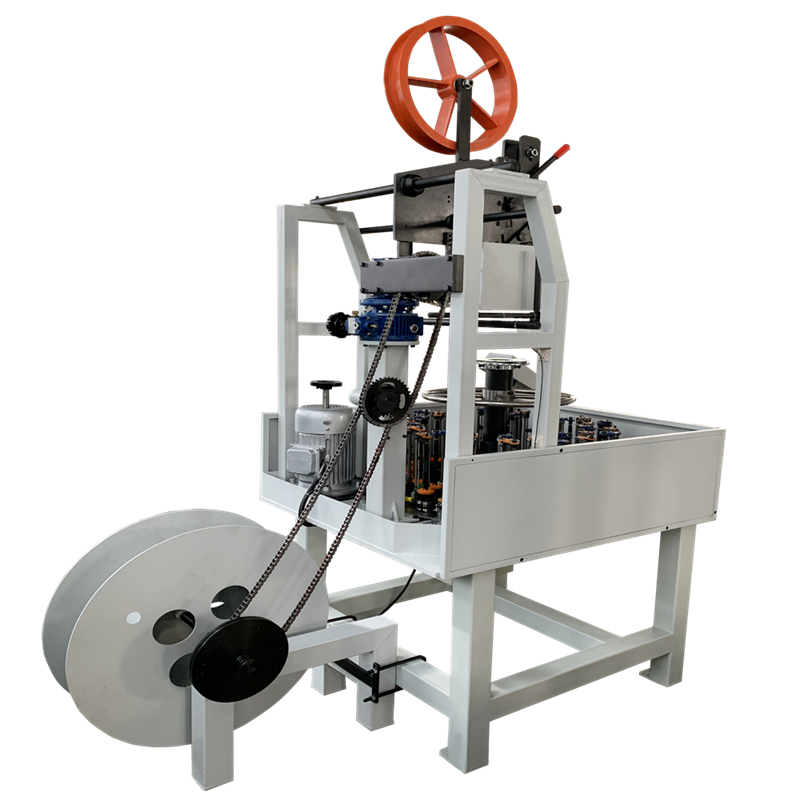

Automation:

Equipped with advanced automation features, such as programmable controls and sensors, to enhance efficiency and reduce manual intervention. Automation contributes to consistent braiding quality.

Speed and Production Output:

High-speed capabilities suitable for industrial-scale production, ensuring efficient manufacturing of sprayer hoses.

Tension Control:

Effective tension control mechanisms to maintain uniform braiding quality. Precise tension control is vital for the integrity of the final sprayer hose product.

User-Friendly Interface:

Intuitive and user-friendly control panel for ease of operation, allowing operators to set and monitor various parameters easily.

Quality Control:

Real-time monitoring features and quality control mechanisms to ensure the production of high-quality and reliable sprayer hoses.

Maintenance and Support:

Designed for easy maintenance with readily available support and spare parts. Regular maintenance is essential for prolonged machine life.

Compliance with Standards:

The machine complies with industry standards and regulations for the manufacturing of hoses used in sprayer applications, ensuring product quality and safety.

The Sprayer Rubber PTFE Teflon Hose Braiding Machine is an indispensable tool for manufacturers in industries where hoses with a combination of rubber and PTFE materials are required, particularly in applications such as agricultural and industrial spraying. It combines precision engineering with advanced automation to deliver efficient and reliable braiding for hoses used in sprayer systems.

Please do not hesitate to contact us, We can provide detailed information based on your specific requirements and applications.